EPDM Rubber Encyclopedia

-

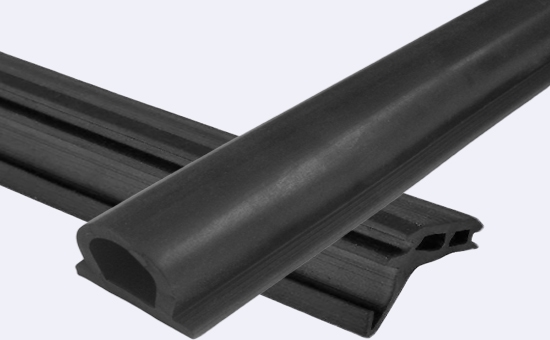

When using EPDM rubber to produce sealing strips, a proper amount of moisture absorbent is required. Calcium oxide is the most common moisture absorbent. In different production processes and different sealing …

-

Epdm rubber products production can be filled with a large amount of rubber oil or filler, mold is easy to product scale, rubber products manufacturers need to design a reasonable system, select the appropriate…

-

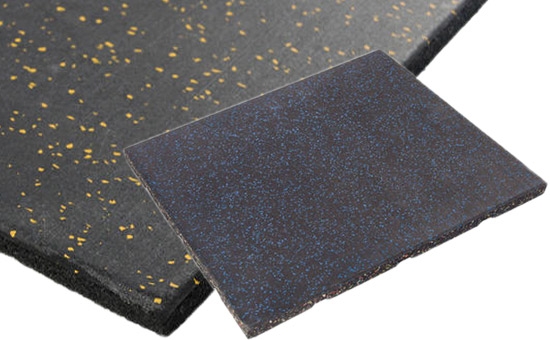

When using EPDM reclaimed rubber to produce low-cost outdoor fitness cushioning pads, rubber product manufacturers need to choose appropriate EPDM reclaimed rubber, rationally design product formulas, appropria…

-

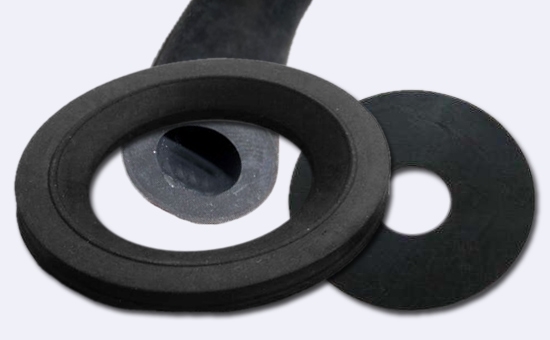

When using EPDM reclaimed rubber as the main raw material to produce rubber seals, rubber products manufacturers can use butadiene rubber and styrene butadiene rubber in an appropriate amount, and rationally de…

-

When EPDM/reclaimed rubber is blended with PP material, the scratch resistance of the blended material directly affects its application range and service life. Rubber and plastic material processing enterprises…

-

When using EPDM rubber to produce extruded sealing strips, the rubber mixing effect directly affects the performance and life of the product. So which rubber mixing machine should be used for EPDM extruded rubb…

-

When using EPDM reclaimed rubber to produce electrical insulating rubber products, rubber product manufacturers need to select EPDM reclaimed rubber reasonably, adjust the rubber product formula appropriately, …

-

EPDM reclaimed rubber can be used in the shipping industry, culture, education, sports, or daily life. The reasonable use of EPDM reclaimed rubber in these fields can achieve the multiple purposes of ensuring q…

-

EPDM reclaimed rubber can be used in the production of various industrial rubber products, rubber and plastic modification or household appliances accessories. The amount of reclaimed rubber is controlled accor…

-

EPDM reclaimed rubber can be used in the production of automobile rubber parts, wires and cables, and shock-absorbing materials. It can reduce the cost of raw materials under the premise of ensuring quality; th…

-

Mixing a proper amount of EPDM compound into butyl rubber, nitrile rubber, polyethylene material or oil-extended ethylene propylene rubber can significantly improve the processing performance of the product and…

-

Appropriate use of EPDM or EPDM reclaimed rubber in certain types of rubber products can improve the overall performance of rubber products, especially the aging resistance. EPDM plays different roles in differ…

-

The combined use of EPDM and natural rubber can improve the comprehensive index of the product. How to realize the co-vulcanization of two kinds of rubbers with obvious structural differences has become the top…

-

When using EPDM rubber to produce rubber joints, the rational use of EPDM reclaimed rubber can not only reduce costs, but also improve processing performance, so how to choose EPDM reclaimed rubber for rubber j…

-

2020-06-26EPDM automobile hose mixing techniqueWhen using EPDM to produce various types of automotive hoses, rubber product manufacturers need to choose the mixing process reasonably, adjust the mixing process properly, and strictly control the timing of ad…

-

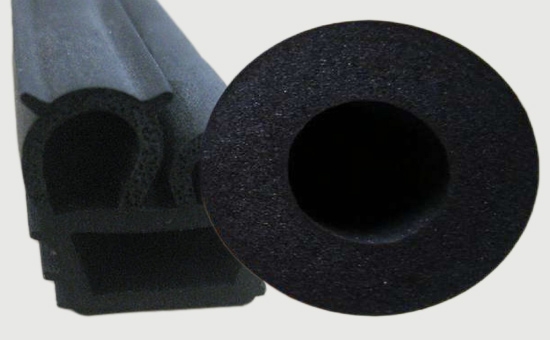

When using EPDM/recycled rubber to prepare sponge foam rubber products, rubber product manufacturers can use styrene-butadiene rubber in an appropriate amount to further improve the wear resistance and anti-sli…

-

When using EPDM and butyl rubber in combination to produce waterproof membranes, rubber product manufacturers need to choose a suitable vulcanization system to further optimize the waterproof membrane finished …

-

When using EPDM reclaimed rubber to reduce the production cost of bathroom rubber pads, rubber product manufacturers need to select the appropriate EPDM reclaimed rubber according to actual needs, reasonably co…

-

When EPDM rubber is used to produce rubber products, rubber product manufacturers can improve the tensile strength of rubber compounds by adjusting the vulcanization system and reinforcing filling system, to ex…

-

When butyl rubber is used to produce heat-resistant foamed rubber products, rubber product manufacturers can blend EPDM or recycled rubber in an appropriate amount according to actual needs to further improve t…