Rubber Chem Encyclopedia

-

When producing rubber products using nitrile reclaimed rubber as the main raw material, sulfur is the most commonly used vulcanizing agent. How much sulfur is appropriate to add? Which accelerators are more sui…

-

Rubber softening plasticizers are mainly used to improve the processing performance of rubber compounds, including reducing the viscosity and increasing the flexibility of the rubber, facilitating mixing, calen…

-

Compared to virgin rubber, reclaimed rubber has lower physical and mechanical properties; carbon black is the most commonly used rubber reinforcing agent and can significantly improve the mechanical strength of…

-

What types of rubber oils are used in blending reclaimed rubber? How do you choose the right rubber oil? What oil is used for blending reclaimed rubber? This is directly related to the type of reclaimed rubber,…

-

In oil-resistant rubber product formulations, the reasonable use of reclaimed rubber (oil-resistant nitrile reclaimed rubber) can effectively reduce raw material costs. When producing oil-resistant rubber produ…

-

As a mainstream raw material for reducing the cost of rubber products on the market, can reclaimed rubber be used in the production of heat-resistant rubber products? Which types of reclaimed rubber can be used…

-

When producing heat-resistant rubber products using reclaimed rubber, the formulation design of the rubber products directly affects the heat resistance of the finished product, especially the additives in the …

-

Reclaimed rubber can be used alone or combined with suitable types of natural or synthetic rubber to produce rubber sealing strips, reducing costs. When using reclaimed rubber to produce rubber sealing strips, …

-

Different types of carbon black have varying reinforcing effects in reclaimed rubber compounds. Manufacturers of reclaimed rubber products need to choose one or several types of carbon black according to actual…

-

When producing composite products that require reinforcement with skeleton materials using recycled rubber as the main raw material, the commonly used adhesive systems are mainly divided into two types: formald…

-

When producing rubber products using regenerated rubber, the selection of rubber materials, formulation design, processing technology, and product performance optimization directly determine the quality, perfor…

-

Unreasonable design of rubber formula, unqualified pretreatment of raw materials and improper operation of mixing and vulcanization process will lead to bubbles. Today, I will share with you how to design the f…

-

When using recycled rubber to produce rubber conveyor belts, seals, rubber soles and other products, the rubber compound is required to have good wear resistance. To improve the wear resistance of recycled rubb…

-

Recycled rubber is widely used in the production of various model rubber products. When using recycled rubber to produce rubber model products, the material, dimensional accuracy, exhaust and ease of mold openi…

-

As a renewable resource for waste rubber recycling, recycled rubber can replace the appropriate proportion of natural rubber and synthetic rubber to produce model rubber products, effectively reducing raw mater…

-

Recycled rubber is made from the desulfurization of waste rubber products, with the basic performance characteristics of rubber, the price is very low, the production of rubber asphalt waterproof coating can no…

-

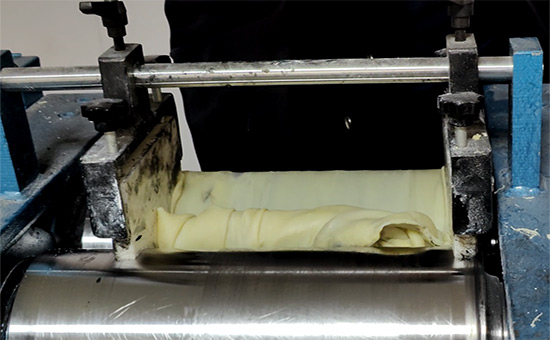

When using recycled rubber to produce thin, thin-walled, long strips or strips, the calendering process is often used. Recycled rubber product manufacturers can meet higher precision calendering requirements th…

-

When the recycled rubber is mixed and pressed on the calender and calendered on the calender, the rubber is required to have good rolling properties, otherwise it is difficult to operate smoothly.

-

As an ideal raw material to replace high-priced raw materials on the market, recycled rubber can be used alone or in combination with corresponding varieties of raw rubber to produce heat-resistant rubber produ…

-

Recycled rubber can be used alone or in combination with suitable varieties of raw rubber to prepare various sponge foam rubber products, effectively reducing the cost of raw materials. When using recycled rubb…