Rubber Chem Encyclopedia

-

When using recycled rubber to produce sponge foam rubber products, the combination of various additives in the filler system directly affects the processing performance of the foam rubber, as well as the streng…

-

Eco-friendly rubber oil is an environmentally friendly rubber product that has a lower environmental impact and higher sustainability. In the context of the current environmental awareness, more and more consum…

-

2023-09-28环保型植物松焦油可以用于出口制品吗?Vegetable pine tar, derived from natural plants, is made through a special extraction process, which has the characteristics of renewable and biodegradable, which makes it unique in the field of environmentally…

-

Recycled rubber will produce some unavoidable odors in the production or processing of rubber products, especially low-cost reclaimed rubber, which is used in the production of rubber products, and usually need…

-

Vegetable pine tar is a dark brown to black viscous liquid with a special odor, also known as pine tar or pine oil, which is a commonly used softener and plasticizer in the rubber industry. Many reclaimed rubbe…

-

Plastics can be used to make a variety of domestic and industrial products. In the production process of plastic products, some pungent odors may be produced, which are generally mitigated by using deodorants. …

-

Pine tar is a natural product extracted from pine wood, which has strong adhesion and waterproofness, and has a wide range of applications in rubber products. Pine tar can be used as an adhesive, plasticizer an…

-

Solve the problem of surface loss of light of summer extruded rubber products: choose high-quality rubber and additives, adjust extruder parameters, match reasonable formula ratio, select high ethylene rubber, …

-

The use of rubber reinforcing agents in rubber products can not only reduce the specific gravity and raw material cost to achieve energy saving and consumption reduction, but also improve the tensile strength o…

-

Because recycled rubber will release some special taste during processing and use, this leaves people with the impression that the quality of recycled rubber is relatively poor or the recycled rubber is not goo…

-

The surface of recycled rubber products is smooth and oily and not white, and it is necessary to pay attention to the vulcanization formula combination and the vulcanization process of mixed rubber to avoid exc…

-

Rubber smell may have a certain impact on the human body but basically will not cause long-term health problems, ventilation, washing, sun drying and other methods to effectively remove rubber smell, most rubbe…

-

The rubber deodorant adopts environmentally friendly single-porous inorganic adsorbent and activated polymer Pings as the main raw materials, which can effectively decompose and adsorb irritating odors such as …

-

Recycled rubber production: Some rubber accessories are needed to improve the performance and processability of rubber during the processing of rubber products. Commonly used excipients include antioxidants, pl…

-

Commonly used additives for recycled rubber include benzothiazoles, mercaptos, aldehydes, amines, organic carboxylic acids, etc., including M/DM/CZ/TMTD, etc. The main function of the accelerator is to accelera…

-

Regenerated rubber reinforcing agent is a substance that can enhance the mechanical properties and durability of rubber. Common reclaimed rubber reinforcing agents include: carbon black, silica, zinc oxide, mag…

-

When using recycled rubber to produce rubber products, selecting appropriate mechanical property modification additives can further improve the mechanical properties of recycled rubber, including tear strength,…

-

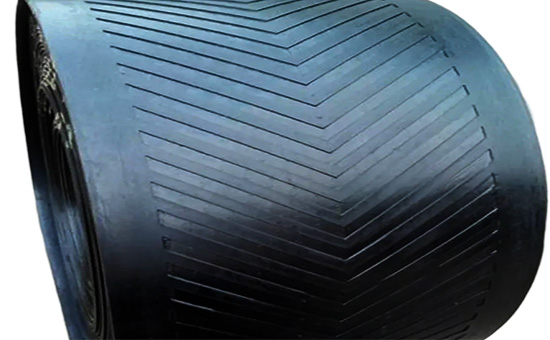

The performance requirements of rubber conveyor belts vary in different usage scenarios, and the raw materials used vary greatly. Recycled rubber, as a new raw material for reducing the cost of rubber products,…

-

According to chemical structure, accelerators can be divided into thiazole type, sulfonamide type, thiuram type, disulfide carbamate type, guanidine type, thiourea type accelerators, etc. Different types of acc…

-

In actual production, if impurities are contained in the formulation, it will not only reduce the physical and mechanical strength of the reclaimed rubber vulcanizate, but also cause production accidents in ser…