Rubber Chem Encyclopedia

-

Supplementary processing must be carried out for mixtures whose quality and technical performance do not meet the requirements, mainly including crushing of solid mixtures, drying and screening of powdered mixt…

-

When using recycled rubber to produce rubber products, especially rubber products with relevant environmental protection requirements, it is not only necessary to choose environmentally friendly recycled rubber…

-

Antioxidants can be divided into polluting and non-polluting antioxidants; When using recycled rubber to produce light-colored recycled rubber products, it is recommended to use non-polluting and non-discolorin…

-

When using recycled rubber to produce rubber products, proper use of lubricant can improve the processing performance of rubber, reduce production energy consumption, and improve the product yield.

-

When using recycled rubber to produce rubber products, vulcanized rubber powder, short fiber and wood powder are also commonly used organic reinforcing agents and fillers. Reasonable addition can improve the te…

-

When using recycled rubber to produce rubber products, organic reinforcing agents and fillers are often used, mainly including phenolic resin, petroleum resin, vulcanized rubber powder, short fiber and wood pow…

-

The short fiber itself has a large length diameter ratio, which is difficult to mix and disperse in the recycled rubber, and generates large heat during mixing. Therefore, when using short fiber for reinforceme…

-

The reclaimed rubber vulcanizate has strength property and elastic relaxation property under static load. The strength property index indicates the resistance of vulcanizate to damage under the action of mechan…

-

Insoluble sulfur will be evenly dispersed in the rubber mixture and insoluble in rubber, so it is difficult to spray frost when the amount is large. Therefore, it is recommended to use insoluble sulfur when the…

-

Petroleum based softeners mainly include alkane oil, aromatic oil, naphthenic oil, machine oil, transformer oil, etc. Different types of softeners have different effects on the properties of recycled rubber com…

-

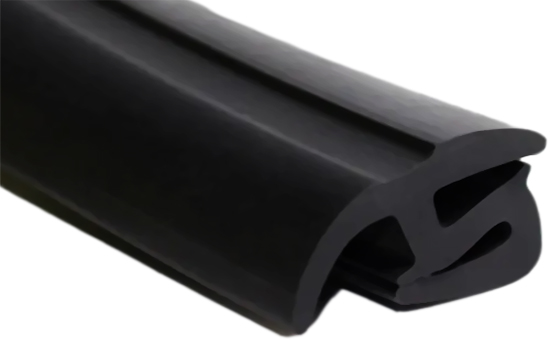

When designing the formula of reclaimed rubber extrusion compound, it is necessary to fully consider the extrusion expansion rate; The design of reinforcement filling system directly affects the extrusion expan…

-

With the continuous progress of recycled rubber production technology, more and more recycled rubber can be used in the production of environment-friendly rubber products, which can effectively reduce the cost …

-

When using recycled rubber to prepare low-cost sponge rubber products, the rubber compound needs to meet certain requirements, specifically in plasticity, matching of foaming rate and curing rate, heat transfer…

-

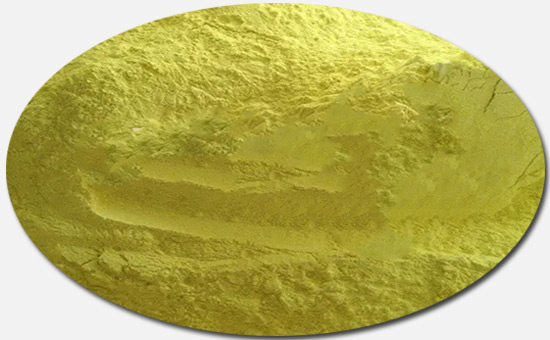

There are six main types of sulfur used in the rubber industry: sulfur powder, precipitated sulfur, insoluble sulfur, colloidal sulfur, sulfur mixture and surface-treated sulfur, among which sulfur powder and i…

-

When using latex reclaimed rubber to produce colored rubber products, the selection of colorants is very important; a full understanding of the properties of rubber colorants helps to correctly select colorants…

-

The level of rubber content in the rubber formulation not only determines the main performance, quality and cost of the product, but also affects the processing performance of the rubber compound. When using re…

-

Inorganic active agents commonly used in the production of reclaimed rubber products include metal oxides, hydroxides, carbonates, and organic active agents mainly include fatty acids, weak amines, soaps, polyo…

-

2022-07-07改善再生胶压出性能如何设计配方更好When using reclaimed rubber to produce rubber products, the manufacturer of reclaimed rubber products must fully consider the process performance, that is, the expansion-shrinkage phenomenon, when designing the…

-

In actual production, proper design of the formulation components of EPDM reclaimed rubber products can further optimize product quality while reducing costs. The editor will focus on sharing with you the vulca…

-

In the production of different reclaimed rubber products, some products use a certain antioxidant alone, and most reclaimed rubber products use two or more antioxidants together. Why? This is mainly because dif…