Rubber Chem Encyclopedia

-

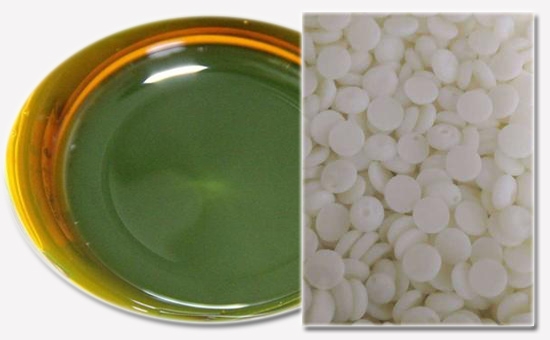

The solubility of ordinary sulfur in rubber increases with the increase of temperature. The solubility of sulfur in different types of rubber is different. The amount of sulfur required in the production proces…

-

Sulfur vulcanizate has the advantages of high tensile strength, wear resistance, fatigue and crack resistance, and good dynamic and static mechanical properties. In actual production, different types of rubber …

-

When using reclaimed rubber to produce heat-resistant rubber products, rubber product manufacturers need to select suitable heat-resistant rubber/reclaimed rubber, and rationally design the matching system, esp…

-

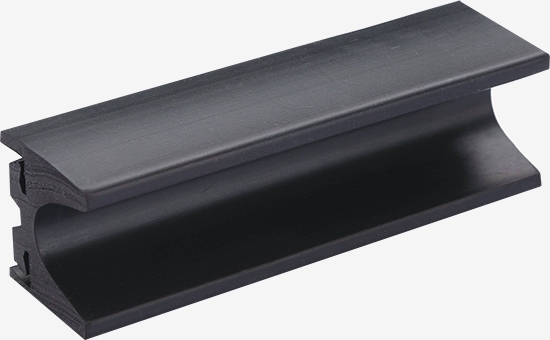

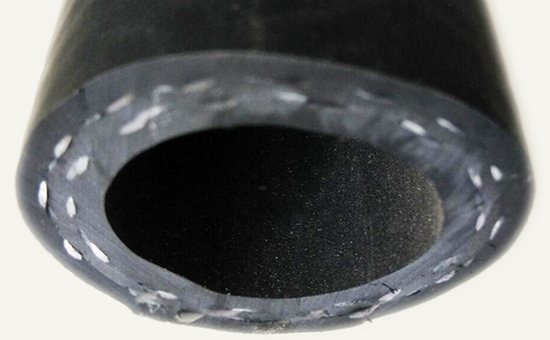

In the production of rubber hoses, choosing appropriate framework materials can increase the strength and rigidity of the hose. Commonly used framework materials are wire and fabric. The framework materials use…

-

When using EPDM/butyl reclaimed rubber to prepare rubber hoses, the design of the vulcanization system directly affects the index of the finished hose, including aging resistance, compression set, etc. It is re…

-

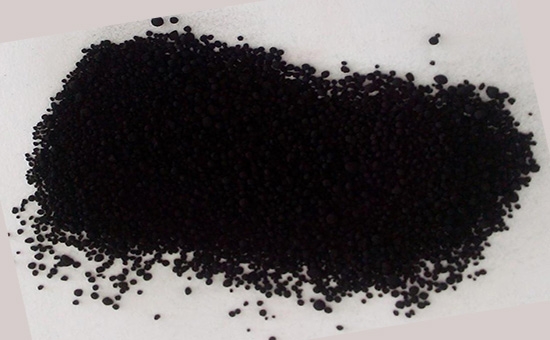

When carbon black is used to reinforce butyl rubber or butyl reclaimed rubber, different types of carbon black have different effects in butyl rubber. Rubber products manufacturers should choose suitable types …

-

When using nitrile rubber or nitrile reclaimed rubber to produce rubber products, carbon black is a commonly used reinforcing agent. The type and amount of carbon black directly affect the compression set perfo…

-

White carbon black is a commonly used white reinforcing filler in the production of rubber products, and its reinforcing effect is second only to carbon black. When silica is used to reinforce rubber products, …

-

When using rubber fillers to reduce the raw material cost of rubber products, rubber product manufacturers need to comprehensively consider the physical properties of rubber products and production costs, and r…

-

When using silica to reinforce tires, rubber product manufacturers need to choose appropriate modifiers or use highly dispersible silica to further improve the reinforcing effect of silica in tires.

-

When using reclaimed rubber to produce injection-type reclaimed rubber products, rubber product manufacturers need to appropriately adjust the rubber product formula according to actual needs, especially the co…

-

When using reclaimed rubber to produce corrosion-resistant rubber products, rubber product manufacturers need to select appropriate rubber compounding agents according to actual needs to further improve the cor…

-

When using reclaimed rubber to produce rubber products, the selection of appropriate curing agent is the basis to ensure the quality of reclaimed rubber products. What are the common curing agents in the produc…

-

When using reclaimed rubber to produce electrical insulation rubber products, rubber product manufacturers need to select appropriate types of rubber softeners and antioxidants in the formula to improve the ele…

-

When using reclaimed rubber to produce rubber products, the surface properties of the rubber filler affect the vulcanization effect and speed of the reclaimed rubber, especially the pH value and DBA of the fill…

-

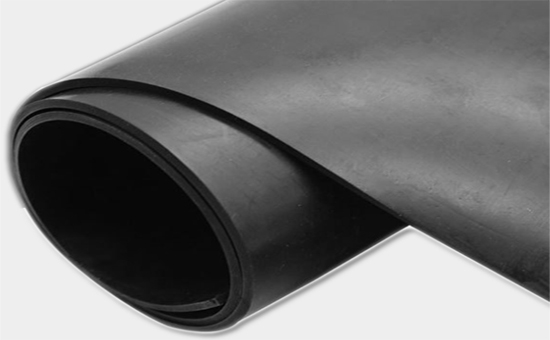

When using natural rubber and styrene-butadiene rubber to produce ordinary environmentally friendly conveyor belt cover rubber, rubber product manufacturers need to select appropriate rubber raw materials, rati…

-

When using reclaimed rubber to produce electrical insulating rubber products, rubber product manufacturers can reasonably design vulcanization systems and rubber fillers according to actual needs to improve the…

-

When using reclaimed rubber to produce rubber products, rubber product manufacturers need to use lubricants, release agents, dispersants, softeners, peptizers, etc., and different processing modifiers play diff…

-

In the formulation of reclaimed rubber products, p-phenylenediamine antioxidants are very common, such as 4000 series antioxidants such as 4010/4010NA/4020, antioxidant H, etc., which can be used alone or in co…

-

When using rubber fillers to reinforce or fill reclaimed rubber, rubber product manufacturers need to understand the impact of filler properties on the reclaimed rubber mixing process, use rubber fillers reason…