When using reclaimed rubber to produce rubber products, the rollability, fluidity and shrinkage of reclaimed rubber are the three major indicators to measure the processing performance of the rubber; rubber product manufacturers need to coordinate the relationship between these three through the cooperation of compounding agents. In actual production, the shrinkage rate of reclaimed rubber directly affects the dimensional stability, performance and life of reclaimed rubber products. So which compounding agents are more beneficial to the shrinkage of reclaimed rubber? What effect will various compounding agents have on the roll-wrapping and fluidity of the rubber compound?

1. Which carbon black is more beneficial to the shrinkage rate of reclaimed rubber

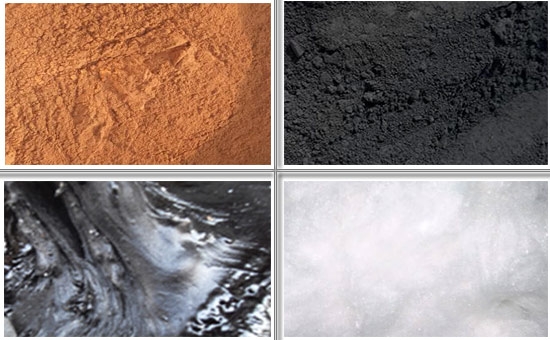

When reclaimed rubber is used to produce rubber products, the addition of general reinforcing agents can reduce the elastic deformation and shrinkage of the rubber. The reclaimed rubber with high structure and small particle size reinforcing agents has a small calendering shrinkage. Therefore, semi-reinforcing carbon black with high structural degree, such as N765, has good extrusion performance, and the extrusion shrinkage of rubber material is lower than that of carbon black N774/N762 and other types of large particle furnace blacks. It is suitable for the production of tire plies, inner tubes, and rubber tubes. , Cable sheath and extruded rubber products.

When white carbon black is selected for reinforcement of rubber products produced by natural reclaimed rubber, adding zinc oxide and small medicines in advance in the late stage of mixing can reduce the shrinkage of the rubber.

2. The influence of inorganic fillers on the shrinkage of reclaimed rubber

In actual production, non-reinforcing rubber fillers can reduce the shrinkage of the rubber to a certain extent. For example, clay 2LLYY728 can increase the viscosity of the rubber, increase the stiffness of the rubber, and reduce the shrinkage of the rubber. The wood powder made by grinding wood can improve the stiffness of the rubber material and control the shrinkage rate of the semi-finished reclaimed rubber. It is suitable for the production of rubber soles and rubber toys.

3. The effect of softener on the shrinkage of reclaimed rubber

During the processing of reclaimed rubber products, the addition of softeners can reduce the intermolecular force of the rubber, shorten the relaxation time of the rubber, improve the fluidity of the rubber, and reduce the shrinkage of the rubber. In the production of reclaimed rubber products, black ointment can not only promote the uniform dispersion of fillers, improve the smoothness of the rubber surface, but also reduce the shrinkage of the rubber and reduce the sulfur ejection in the rubber.

4. The influence of skeleton materials on the shrinkage of reclaimed rubber

Nowadays, many reclaimed rubber products will choose to use framework materials to further improve the mechanical strength and other indicators of the products in the production process. Commonly used are natural fibers, synthetic fibers, and metal materials. Among them, nylon in synthetic fibers has high strength but low initial modulus, large heat shrinkability, poor dimensional stability, and poor adhesion to reclaimed rubber; B fiber in aramid fiber has high strength, small elongation, and almost no shrinkage.

In actual production, the use of different types of compounding agents has different effects on the shrinkage of reclaimed rubber, and the same compounding agent has different effects in different types of reclaimed rubber. Manufacturers of reclaimed rubber products need to select appropriate types of compounding agents according to actual needs, coordinate the relationship between the roll properties, fluidity and shrinkage of reclaimed rubber bags, and further improve the processing performance and use performance of reclaimed rubber products.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits