EPDM rubber and EPDM reclaimed rubber have excellent resistance to high and low temperature and anti-aging properties, and are widely used in rubber products industry. In the EPDM compound formula, flame retardant treatment can be further expanded with flame retardant treatment. The application range of ethylene propylene rubber and reclaimed rubber. So what kind of flame retardant should be selected when using EPDM rubber to produce flame retardant rubber products? How does the flame retardant work?

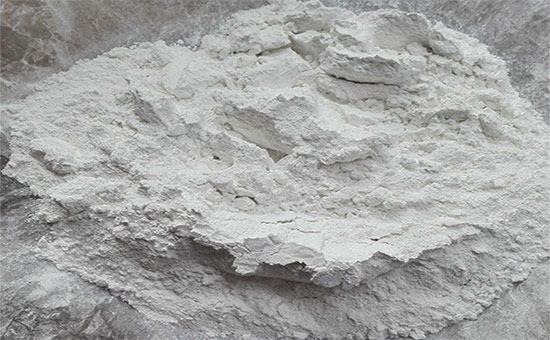

EPDM rubber and EPDM reclaimed rubber are all flammable substances. They will spontaneously ignite at a certain temperature and will burn under conditions of fire or oxygen. In order to improve EPDM rubber products for certain special occasions. For safety, flame retardant treatment of EPDM rubber is required. Commonly used flame retardants can be divided into organic flame retardants and inorganic flame retardants. Chlorinated paraffins, chlorinated polyethylene, tetrabromoethane, triphenyl phosphate and tricresyl phosphate are common products in organic flame retardants. Among the inorganic flame retardants, hydroxides such as aluminum hydroxide, magnesium hydroxide and cerium oxide in metal oxides are more common.

When selecting a flame retardant for EPDM flame retardant products, a single flame retardant may not meet the demand. It is often necessary to use two or more flame retardants together. In this case, it is necessary to consider the synergy between the flame retardants. Effects and confrontation effects.

1 Synergistic effect of flame retardant: The so-called synergistic effect is that the flame retardant effect of two or more flame retardants when used together is better than that of a single flame retardant. The EPDM compound uses a combination of antimony trioxide and FR-1 in a ratio of 3/1 to produce a better flame retardant effect. The EPDM flame retardant compound can also be used in combination with an organic oxide and a halogen to produce a flame retardant effect.

2 The anti-effect effect of flame retardant: In the multi-class flame retardant, if two or more flame retardants are used together, synergistic effect will be produced, and improper use will weaken the flame retardant effect of the flame retardant, that is, confrontation effect. When calcium carbonate and PX system flame retardant are used together, calcium carbonate will eliminate halogen and other acid gases, and will not delay the fire, thereby weakening the flame retardant effect; hydrazine and nitrous acid have antagonistic effects, so the lanthanide and phosphorus flame retardants cannot Use together. The above combination should be noted when using flame retardant rubber products made of EPDM or recycled rubber.

In EPDM flame retardant rubber products, replacing some EPDM rubber with EPDM reclaimed rubber can reduce the cost and ensure the quality of rubber products. Only all rubber product matching systems including flame retardant systems need to be reconsidered. If you are interested, Xiaobian will then talk to you about the flame retardant problem of EPDM/recycled rubber.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits