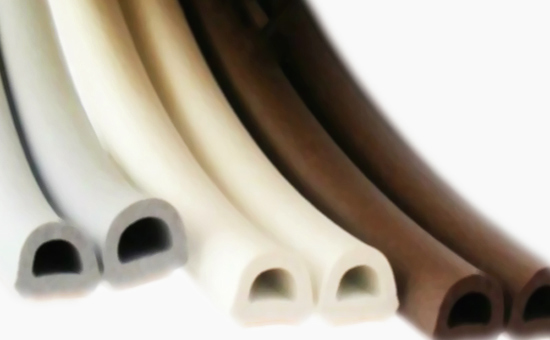

Case background: people are becoming more and more demanding in the United States, and people pay attention to the "collocation", such as door and window seal, color and overall decoration. Therefore, a single three yuan ethylene propylene black sealing strip has been unable to meet the needs of users. Qinghe rubber products enterprises in order to improve market sales, began looking for a suitable raw material to produce color sealing strip, used for doors and windows, cabinets, seals and so on.

Case study: to ask which kind of rubber is best suited for the production of seals, then three yuan EPDM is the best choice. Three EPDM has excellent high temperature performance, high chemical stability, aging resistance, high insulation, sealing strip production is the best choice; but three EPDM color difference, so the rubber products produced are mostly black, the seal is the same; therefore continue to use three EPDM is not appropriate.

Case process: after careful comparison, the customer first decided to use good white latex reclaimed rubber, there are three main reasons, one is the white latex reclaimed rubber color easily, can produce a variety of colors of the seal; two is the reclaimed rubber latex has good elasticity, produced foam rubber products elastic is very high (the customer intends to is the production of color foam seal; three) is white latex reclaimed rubber price is much lower than the three EPDM can significantly reduce the cost of raw materials.

Our sales staff to the customer's demand and choice of good white latex reclaimed rubber reason, recommended the use of customers Hongyun white gray three yuan reclaimed rubber, this is because, first of all, compared with latex reclaimed rubber, three yuan and three yuan to head rubber, unvulcanized EPDM EPDM rubber for three yuan the processing of raw materials can keep the performance of reclaimed rubber three EPDM, in high temperature, anti ageing performance superior to latex reclaimed rubber, can keep good sealing performance in a variety of high and low temperature, sunlight and other harsh environment; secondly, white and gray three EPDM reclaimed rubber and ethylene propylene rubber (other black three yuan including three yuan, three yuan original rubber reclaimed rubber) compared to color, light color, can produce all kinds of rubber seal; in addition, white and gray three EPDM reclaimed rubber is three yuan original About 1/3 of glue price can also greatly reduce raw material cost.

Case tracking: after customer trials, the final decision to use good white gray three yuan reclaimed rubber, both indicators, or production cost considerations from the rubber seal, white grey three EPDM reclaimed rubber is the best choice. The use of Hongyun white grey three yuan ethylene propylene reclaimed rubber production of color foam sealing strip, not only to meet the needs of users, but also to reduce the cost of raw materials, manufacturers profits continue to rise.

Product introduction: Hongyun three white gray EPDM reclaimed rubber rubber content is 50%, tensile strength 9Mpa, elongation 420%, products using the patented production stage desulfurization method, high and low temperature resistance, aging resistance, high insulation, high strength, good elasticity, for the production of doors and windows sealing strip can ensure the product surface smooth and bright, with hundreds of the use of rubber products to reduce the cost of the average in the range of about 20%.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits