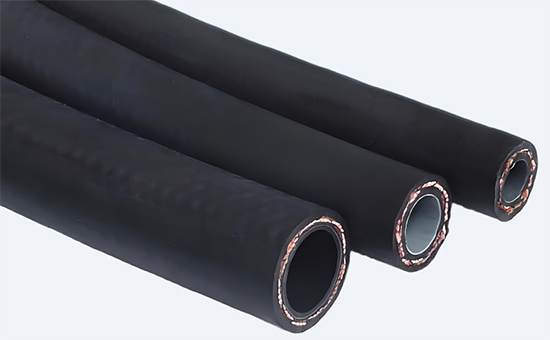

Thin-walled air conditioning pipes are an important part of the air conditioning system, which has the characteristics of light texture, corrosion resistance and high strength to ensure the normal operation of the air conditioning system. EPDM has excellent weather resistance, ozone resistance and heat resistance, making it an ideal raw material for the production of thin-walled air conditioning pipes. However, the cost of thin-walled air conditioning pipes produced entirely from EPDM rubber is high, and it is difficult to win in the intensifying price war; It is imperative to use EPDM reclaimed rubber to replace part of the EPDM original rubber to produce thin-walled air conditioning pipes.

1. Selection skills of reclaimed rubber for thin-walled air conditioning pipes

When thin-walled air-conditioning pipes use EPDM reclaimed rubber to replace part of EPDM rubber to reduce costs, the specific performance requirements of air-conditioning pipes must be fully considered, and it is recommended to choose EPDM reclaimed rubber with high ethylene propylene content to give the rubber good elasticity and better ensure the heat-resistant, low-temperature and aging resistance of air-conditioning pipes; The wall thickness of the thin-walled air conditioning pipe is thinner, and it is recommended to use ultra-fine filtration EPDM reclaimed rubber, which has high fineness and no impurities, so as to ensure the smooth extrusion of the hose and better permeability resistance of the finished product.

2. EPDM rubber/EPDM reclaimed rubber produces the outer rubber vulcanization formula of thin-walled air conditioning pipes

80 parts of EPDM rubber, 20 parts of high-grade EPDM reclaimed rubber, 5 parts of zinc oxide, 1 part of stearic acid, 150 parts of carbon black N550, 20 parts of aromatic oil, 55 parts of naphthenic oil, 1.3 parts of accelerator M, 1.8 parts of accelerator TMTM, 1.6 parts of accelerator TMTD, 1.3 parts of sulfur; Total 337 copies.

60 parts of EPDM rubber, 40 parts of odorless EPDM reclaimed rubber, 5 parts of zinc oxide, 2 parts of stearic acid, 2 parts of antioxidant AP, 110 parts of carbon black N550, 180 parts of carbon black N990, 115 parts of naphthenic oil, 5 parts of plasticizer, 3 parts of accelerator PZ, 3 parts of accelerator BZ, 1.8 parts of accelerator TMTD, 1.2 parts of accelerator TETD, 1 part of vulcanizing agent DTDM, 0.6 parts of sulfur; Total 529.6 copies.

3. The advantages of EPDM reclaimed rubber replacing EPDM rubber in the production of thin-walled air conditioning pipes

EPDM reclaimed rubber retains the basic performance characteristics of EPDM rubber, with good high and low temperature resistance, ozone resistance, weather resistance, the price is much lower than EPDM original rubber, better fluidity and plasticity, less expansion and contraction, and less heat generation for processing. Therefore, the appropriate use of EPDM reclaimed rubber in the thin-walled air-conditioning pipes produced with EPDM rubber as the main raw material can not only effectively reduce the cost of raw materials, but also improve the processing technology performance of the rubber compound, reduce power consumption, and make the size of the finished air-conditioning pipe more stable.

Thin-walled air-conditioning pipes need to have good heat-aging resistance to ensure that air-conditioning pipes maintain good performance in high-temperature environments for a long time, and are not easy to age and deform. Thin-walled air-conditioning pipes require the rubber material to have a certain elasticity and flexibility E4LYY122, as well as sufficient strength to adapt to the vibration and displacement of the air-conditioning system during operation, to ensure tight connection and reduce noise. Air conditioning pipes have low permeability to water and refrigerant, and too high permeability can lead to refrigerant leakage or water accumulation in the air conditioning system, resulting in system blockage, parts corrosion and other problems. Thin-walled air conditioning pipes need to maintain a certain elasticity and sealing performance at low temperatures to ensure that the air conditioning system works normally in cold weather.

When using EPDM reclaimed rubber to replace part of EPDM rubber to produce thin-walled air conditioning hoses, rubber product manufacturers must select the appropriate EPDM reclaimed rubber according to the specific needs of the air conditioning pipes, reasonably design the rubber formula, appropriately adjust the production process parameters, and discuss relevant issues with you in the future.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits