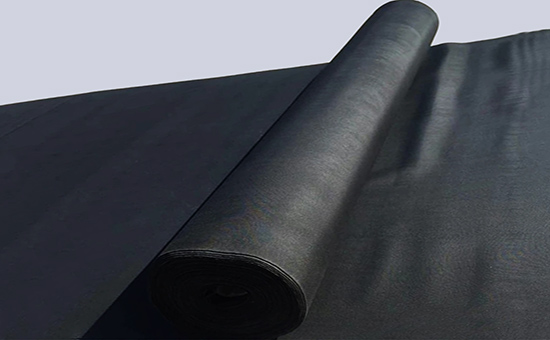

EPDM rubber has excellent ozone resistance, weather resistance, heat resistance, chemical stability, low temperature resistance, electrical insulation, etc., and is widely used in the automotive industry, wire and cable industry, construction and waterproof materials, industrial rubber products, civil products and other fields. When using EPDM rubber to produce rubber products, improving the processing performance of rubber can not only improve production efficiency and yield, but also effectively reduce production costs.

1. Reasonable design of EPDM rubber softening and plasticizing system

The main role of rubber softeners and plasticizers is to improve the processing performance of rubber compounds, including mixing, extrusion, calendering, die fluidity, etc. In actual production, the commonly used softeners of EPDM rubber are paraffin oil, aromatic oil, naphthenic oil, mechanical oil, ointment, petroleum resin, asphalt, pine tar, coumerone, etc.; It is recommended to use paraffin oil for EPDM rubber compounds using peroxide vulcanization, and the dosage is controlled within 30 parts, and aromatic hydrocarbon processing oil is avoided.

2. Use EPDM reclaimed rubber in an appropriate amount

EPDM reclaimed rubber is made of EPDM head glue, unvulcanized EPDM rubber or waste EPDM rubber products (such as automobile sealing strips) as raw materials, after classification, crushing, desulfurization, filtration, refining and molding, the basic performance characteristics of EPDM rubber are retained, and can be used in combination with EPDM rubber in an appropriate proportion to reduce the cost of raw materials and improve the processing technology performance of rubber compounds.

Compared with EPDM rubber, EPDM reclaimed rubber has better plasticity, uniform dispersion of compounding agent, and low mixing power consumption. When EPDM rubber and EPDM reclaimed rubber are used together, the reclaimed rubber E4LYY1121 can play the role of lubricant, and it is easier to produce and press the film; The expansion and contraction of EPDM rubber/EPDM reclaimed rubber combined with unvulcanized rubber are much smaller than those of unvulcanized rubber with only new rubber, and the shape and size of the finished product are more stable.

3. Select the right rubber additives to improve the processing process performance of EPDM rubber

EPDM rubber is a non-polar rubber, with compounding agent, polar rubber affinity is small, dispersion and viscosity is poor, processing rubber products with high fluidity requirements need to use processing aids, commonly used stearic acid, low molecular weight polymer, wax and petroleum resin and other additives.

Stearic acid can be used as an active agent to improve EPDM dispersion, prevent sticking rolls, and improve mold release. Polyethylene wax has good compatibility with ethylene propylene rubber, good internal and external lubrication effect, can improve dispersion and mold release, low product price, and will not affect the vulcanization performance of rubber compound when used. Polyethylene glycol (PEG) can improve flowability, appearance quality and mold release of EPDM products. Petroleum resins can improve the adhesion of EPDM, promote uniform dispersion, and improve flowability. Thermoplastic phenolic resins are used as tackifiers to improve EPDM adhesion to fabrics or metals.

Most of the high-efficiency rubber processing fluids are mixtures, mainly fatty acid soaps, fatty acid esters, etc., which can improve the processing fluidity of rubber by improving the dispersion, low viscosity and surface lubrication effect of EPDM.

To improve the processing performance of EPDM rubber, EPDM rubber/EPDM reclaimed rubber, rubber product manufacturers also need to optimize the production process, such as mixing parameters such as mixing temperature, time, speed, adjust vulcanization temperature, time and pressure, and control the molding temperature, speed, pressure and other process parameters in the molding process such as extrusion, injection and calendering. The editor will continue to discuss related issues with you in the future.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits