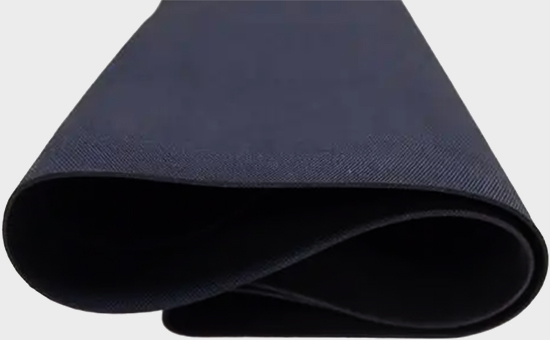

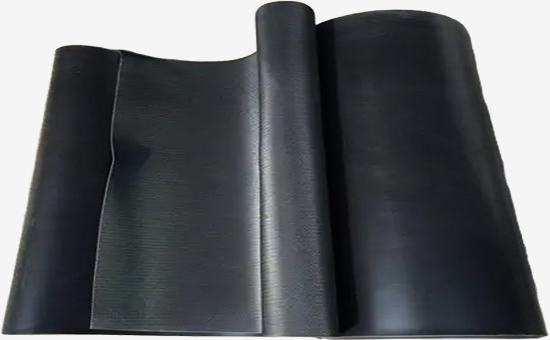

Rubber waterproofing membrane is a sheet waterproof product processed from rubber as the main raw material; EPDM rubber has excellent high and low temperature resistance, ozone resistance and weather resistance, and is the main raw material for the production of rubber waterproofing membranes. With the continuous progress of the production process of reclaimed rubber, the application of reclaimed rubber in the production of rubber products is becoming more and more extensive, and EPDM waterproofing membrane is one of them. Which reclaimed rubber can reduce the cost of EPDM rubber waterproofing membrane, what problems need to be paid attention to when using, and how to design the formula?

1. Which reclaimed rubber can be used in the production of EPDM waterproofing membrane

(1) EPDM reclaimed rubber

EPDM reclaimed rubber is made of waste EPDM rubber and its products such as EPDM head glue, unvulcanized rubber compound, EPDM sealing strip, etc., which retains the basic performance characteristics of EPDM original rubber, has excellent high and low temperature resistance, weather resistance, ozone resistance, and can replace EPDM rubber in whole or in part to produce waterproof membranes, effectively reducing the cost of raw materials on the premise of ensuring the performance of waterproof membranes.

(2) Butyl reclaimed rubber

Butyl reclaimed rubber is made of waste butyl inner tube as raw material, processed by crushing, magnetic separation, regeneration, refining, filtration, molding and other processes, with good air tightness, water resistance, heat resistance, chemical corrosion resistance and other performance characteristics, can be used with EPDM rubber in the appropriate proportion to produce waterproof membrane, reduce costs while further improving the air tightness and water resistance of EPDM waterproofing membrane, and prolong the service life of waterproofing membrane.

(3) Chlorinated butyl reclaimed rubber

Chlorobutyl reclaimed rubber is mostly made of waste medical bottle caps and closures as raw materials, processed through crushing, desulfurization, hot refining, rubber filtration, refining and other processes, with the basic performance characteristics of chlorinated butyl rubber, with good air tightness, heat resistance, weather resistance, flexural resistance, chemical corrosion resistance and other performance characteristics, can be used with EPDM rubber to produce waterproof membranes, improve the processing technology performance of rubber and the aging resistance of finished products, and reduce costs.

2. The application of reclaimed rubber in EPDM waterproofing membrane

When using reclaimed rubber to reduce the production cost of rubber waterproofing membrane, rubber product manufacturers need to select appropriate reclaimed rubber according to the performance requirements of the waterproof membrane, and reasonably determine the mixing method of reclaimed rubber E4LYY1225: EPDM reclaimed rubber, butyl reclaimed rubber, and chlorinated butyl reclaimed rubber can be used with EPDM rubber in appropriate proportions to produce waterproof membranes; EPDM waterproofing membrane can also be mixed with EPDM reclaimed rubber and butyl reclaimed rubber at the same time to further improve the comprehensive performance of waterproofing membrane and reduce more costs.

3. Vulcanization formula of EPDM waterproofing membrane containing reclaimed rubber

(1) EPDM rubber/EPDM reclaimed rubber is used together to produce waterproofing membranes

60 parts of EPDM rubber, 40 parts of EPDM reclaimed rubber, 5 parts of zinc oxide, 1 part of stearic acid, 75 parts of carbon black N330, 20 parts of activated calcium carbonate, 18 parts of heavy calcium carbonate, 5 parts of petroleum resin, 35 parts of naphthenic oil, 1 part of accelerator BZ, 1.5 parts of accelerator DM, 0.8 parts of accelerator PZ, 1.5 parts of sulfur; Total 263.8 copies.

(2) EPDM rubber/butyl rubber/butyl reclaimed rubber is used to produce waterproofing membranes

EPDM rubber 45 parts, butyl rubber 20 parts, butyl reclaimed rubber 35 parts, zinc oxide 3.5 parts, stearic acid 1.2 parts, antioxidant 1.5 parts, carbon black N330 35 parts, clay 50 parts, talc powder 20 parts, paraffin oil 20 parts, accelerator NC 0.65 parts, accelerator TMTD 1 part, accelerator M 1.5 parts, accelerator PX 0.65 parts, sulfur 2 parts; Total 237 copies.

EPDM waterproofing membrane can also be completely used EPDM reclaimed rubber, or combined with butyl reclaimed rubber, which can reduce more costs on the premise of ensuring the performance of the waterproofing membrane. Hongyun environmental protection EPDM reclaimed rubber adopts imported EPDM head glue as the main raw material, which has high and low temperature resistance, anti-aging, high insulation, ozone resistance, erosion resistance and other physical properties, and has the advantages of high glue content, no taste, good elasticity, smooth and bright product surface compared with the sealing strip EPDM regeneration, and is an ideal raw material for replacing EPDM original rubber for the production of waterproof membranes.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits