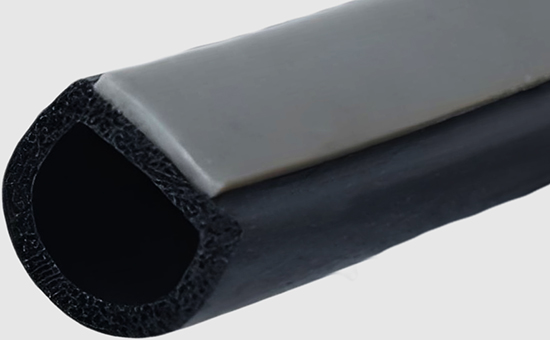

Sponge sealant strips for automobile doors and windows are important auto parts, which are widely used in doors, windows and other parts, playing a good role in sealing and waterproofing, sound insulation and noise reduction, dust and insect prevention, shock absorption and buffering. EPDM reclaimed rubber retains the basic performance characteristics of EPDM rubber, with excellent high and low temperature resistance, ozone resistance and weather resistance, and can be used alone or in combination with EPDM rubber to produce automotive sponge sealing strips to reduce the cost of raw materials.

1. Performance requirements of sponge sealing strips for automobile doors and windows

The sponge sealing strip for automobile doors and windows has the following requirements for the rubber materials used:

(1) Good elasticity and resilience: the sponge sealing strip for automobile doors and windows can quickly return to its original state when it is compressed or acted by external force, and the sealing effect is good.

(2) Aging resistance: automobiles need to be used in various environments and temperatures, and the sponge sealing strips for automobile doors and windows are required to have good ozone resistance, weather resistance, high and low temperature resistance, etc., and can maintain good physical and mechanical properties and sealing properties when exposed to the outside for a long time, and are not prone to cracking, hardening, brittleness and other phenomena.

(3) Good compression set: the sponge sealing strip for automobile doors and windows can maintain a certain elasticity in the compressed state, is not easy to deform, and maintains a good sealing effect for a long time.

(4) Good air tightness: prevent the penetration of air and water.

(5) Environmentally friendly and odorless: non-toxic, odorless and low-volatile rubber raw materials are used to avoid harmful substances affecting human health.

2. Selection tips for EPDM reclaimed rubber for sponge sealing strips for automobile doors and windows

When using EPDM reclaimed rubber to reduce the production cost of sponge sealant strips for automobile doors and windows, it is recommended to choose EPDM reclaimed rubber with high EPDM rubber content to give the sealant good aging resistance E4LYY1216; Choose ultra-fine EPDM reclaimed rubber, with high fineness, no impurities, good air tightness and uniform foaming of the finished rubber strip; Environmentally friendly EPDM reclaimed rubber, no pollution, no radiation, no penetration, meet RoHS testing standards, meet environmental protection requirements and human health standards.

3. EPDM rubber/EPDM reclaimed rubber produces vulcanization formula for sponge sealing strips for automobile doors and windows

Formula (1): 80 parts of EPDM rubber, 20 parts of EPDM reclaimed rubber, 20 parts of zinc oxide, 1 part of stearic acid, 2 parts of antioxidant, 50 parts of carbon black N774, 35 parts of calcium carbonate, 65 parts of clay, 45 parts of paraffin oil, 6 parts of foaming agent DPT, 6 parts of urea, 1 part of triethanolamine, 3.6 parts of accelerator EZ, 1 part of accelerator TT, 2.4 parts of accelerator M, 1 part of sulfur, 5 parts of hygroscopic agent, a total of 344 parts.

Formula (2): EPDM rubber 75 parts, EPDM reclaimed rubber 25 parts, zinc oxide 5 parts, stearic acid 1 part, carbon black N990 25 parts, carbon black N550 50 parts, calcium carbonate 20 parts, naphthenic oil 70 parts, foaming agent ACR 5 parts, accelerator DPG 0.8 parts, accelerator CBS 2 parts, accelerator MBT 3 parts, sulfur 1.5 parts, moisture absorber 5 parts; Total 288.3 copies.

Formula (3): 70 parts of EPDM rubber, 30 parts of EPDM reclaimed rubber, 20 parts of zinc oxide, 5 parts of stearic acid, 50 parts of carbon black N550, 80 parts of calcium carbonate, 30 parts of clay, 50 parts of paraffin oil, 15 parts of black ointment, 2 parts of RX-80 resin, 8 parts of foaming agent AC, 8 parts of urea, 1.5 parts of accelerator CZ, 1 part of accelerator EZ, 1 part of accelerator M, 0.5 parts of accelerator TMTD, 1.5 parts of sulfur, 2 parts of release agent, 5 parts of moisture absorber; Total 380.5 servings.

When EPDM reclaimed rubber is mixed with EPDM reclaimed rubber in the automotive sponge sealing strip produced with EPDM rubber as the main raw material, it is not only necessary to choose the appropriate EPDM reclaimed rubber, but also need to pay attention to the stability of the reclaimed rubber.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits