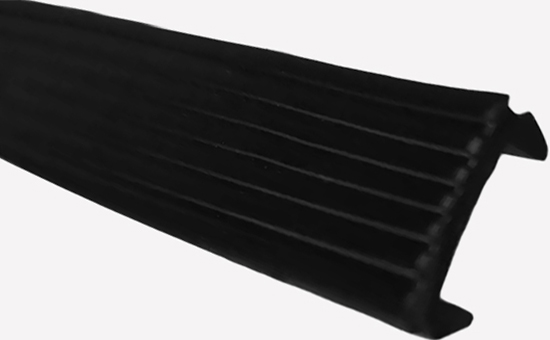

Door and window dust cover is a dustproof accessory installed in the gap among doors and windows, the main function is to block dust, sand and foreign objects from entering the room, is an indispensable part of the modern building door and window system, can be processed by EPDM rubber. Affected by the high cost of EPDM raw rubber, the raw materials for door and window dust covers have gradually shifted to EPDM reclaimed rubber. Can EPDM reclaimed rubber produce rubber door and window dust covers? What problems need to be paid attention to when using reclaimed rubber to reduce the cost of door and window dust covers?

1. Performance requirements for door and window dust covers

(1) Elasticity and flexibility can make the door and window dust cover fit closely into the gaps of doors and windows, effectively block dust and insects from entering the room, and enhance the sealing and dustproof effect.

(2) The dust cover of doors and windows should withstand the influence of natural factors such as long-term wind, sun, rain, cold and heat, and the rubber used needs to have good ozone resistance, weather resistance and aging resistance to ensure that the dust cover is not easy to harden, crack and aging for long-term use.

(3) The dust cover of doors and windows needs to withstand frequent opening and closing friction during installation and use, and the rubber material has sufficient tensile strength and wear resistance, and the dust cover will not be easily damaged by external force, and the sealing effect is maintained for a long time.

(4) Door and window dust covers need to withstand the erosion of corrosive substances such as acid rain, salt spray, and detergents during use, and the rubber material is required to have good corrosion resistance.

2. The advantages of EPDM reclaimed rubber in the production of door and window dust covers

EPDM reclaimed rubber is processed from EPDM waste rubber or waste EPDM rubber products as raw materials, which retains the basic performance characteristics of EPDM original rubber, with excellent high and low temperature resistance, weather resistance, ozone resistance and aging resistance, and can provide basic elasticity, hardness, tensile strength and wear resistance for door and window dust covers, meet the performance requirements of door and window dust covers, and can replace EPDM original rubber to produce door and window dust covers and reduce costs.

Compared with EPDM rubber, EPDM reclaimed rubber has low price, better fluidity and plasticity, less heat generation for processing, and the expansion and contraction of unvulcanized rubber during processing are much smaller than that of unvulcanized rubber with only new rubber, and the size of the finished product is more stable.

3. Application skills of EPDM reclaimed rubber in door and window dust covers

(1) The proportion of reclaimed rubber blending

When EPDM reclaimed rubber is used for door and window dust covers, EPDM reclaimed rubber can be selected to replace EPDM original rubber in whole or in part according to the physical property requirements and cost budget of the dust cover. Door and window dust covers have high requirements for aging resistance, and the proportion of EPDM rubber can be appropriately increased; If the cost control is stricter, the mixing ratio of EPDM reclaimed rubber can be appropriately increased on the premise of meeting the basic performance of door and window dust covers.

(2) Key points of the formula design of EPDM reclaimed rubber for the production of door and window dust covers

EPDM reclaimed rubber can be used to produce door and window dust covers, sulfur-accelerator system or peroxide vulcanization system, sulfur vulcanization system is low cost, simple operation, peroxide vulcanization system is suitable for products with high requirements for heat resistance, compression set resistance E5LYY17 permanent set; Commonly used reinforcing agents are carbon black (to improve the tensile strength and wear resistance of reclaimed rubber door and window dust covers), silica, etc., and fillers include calcium carbonate, clay, etc.; the use of paraffin oil or paraffin oil as plasticizers; Appropriate use of antioxidants, or combined with paraffin, to prolong the service life of EPDM reclaimed rubber door and window dust covers.

When using EPDM reclaimed rubber to produce dust covers for doors and windows, rubber product manufacturers also need to appropriately adjust the production process parameters, especially the mixing and vulcanization processes, and continue to discuss related issues with you in the future.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits