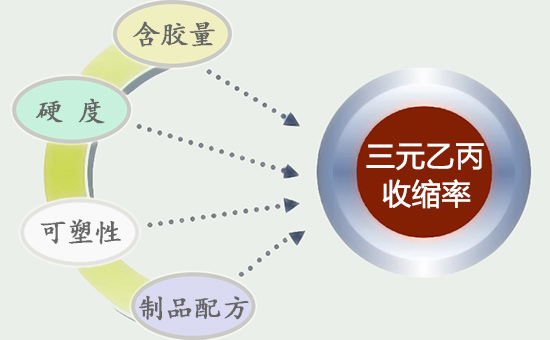

EPDM reclaimed rubber is high and low temperature, anti-aging properties of the best reclaimed rubber, at the same time, its shrinkage in the reclaimed rubber products is also the largest, said the rubber compound in the suppression of heating vulcanization process, rubber Internal deformation and cross-linked thermal expansion force generated in the cooling stress tends to eliminate the best proportion. EPDM reclaimed rubber shrinkage factors have many effects, if you want to choose a good shrinkage of ethylene-propylene reclaimed rubber, may wish to consider the following aspects:

1, EPDM reclaimed rubber containing plastic volume: Under normal circumstances, EPDM reclaimed rubber with higher plastic content, the greater the shrinkage of the product, which is due to the higher content of plastic reclaimed rubber inside the The higher the content of rubber hydrocarbons; such as rubber content of 70% Hongyun import EPDM Recycled plastic content of 55% Hongyun BD EPR shrinkage rate to be larger.

2, EPDM reclaimed rubber hardness: the higher the general hardness of EPDM reclaimed rubber shrinkage the greater.

3, EPDM reclaimed rubber plasticity: EPDM reclaimed rubber plasticity, the better the fluidity, the smaller the shrinkage of reclaimed rubber.

The use of EPDM reclaimed rubber production rubber products, the size of the shrinkage and does not respond to the appropriate plastic material, rubber shrinkage and shrinkage of rubber products required the closest is the best. If it is necessary to adjust the shrinkage of EPDM rubber products, rubber formulations can be adjusted by recipes, production processes and other ways to change the rubber shrinkage.

EPDM reclaimed rubber products formula, the greater the amount of sulfur, the greater the shrinkage of reclaimed rubber; reinforcing agent, filler, the more the smaller the shrinkage rate; EPDM vulcanized rubber vulcanizing temperature increase of 10 ℃, the shrinkage of reclaimed rubber increases by 0.1% ~ 0.2%.

EPDM shrinkage shrinkage than latex reclaimed rubber, nitrile rubber reclaimed rubber and other products have a larger shrinkage rate, but not all of the EPDM reclaimed rubber products have higher shrinkage rate than other types of reclaimed rubber The shrinkage of recycled rubber products is related to the shape, mold and thickness of rubber products. For example, the shrinkage of thin products (section thickness less than 3mm) is 0.2% ~ 0.6% larger than that of thick products (10mm or more) On the reclaimed rubber shrinkage problem is not a few words can be made clear,what are your new discoveries?

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits