Rubber Chem Encyclopedia

-

Vulcanization is a process in which the rubber compound forms a three-dimensional network structure through intermolecular cross-linking of the raw rubber. The vulcanization system directly affects the finished…

-

When EPDM rubber and EPDM reclaimed rubber are used together to produce rubber products, the mixing process is mostly carried out in an internal mixer, and the variety and amount of rubber additives directly af…

-

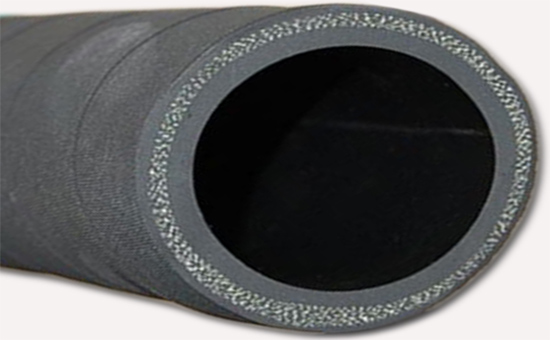

The inner rubber of the coreless cloth clamping hose in the cloth clamping hose is mainly processed with natural rubber, cis-1,4-butadiene rubber and styrene butadiene rubber as the main raw materials. A large …

-

In order to improve production efficiency, reclaimed rubber products are prone to scorch when the operating temperature of kneading, calendering, etc. is increased, or a high-temperature rapid vulcanization sys…

-

When using short fiber reinforced reclaimed rubber, the reclaimed rubber is the continuous phase and the short fiber is the dispersed phase, and an interface layer will be formed among the two phases. strong ef…

-

The formula of reclaimed rubber products is mainly composed of raw rubber, vulcanization system, anti-aging system, reinforcing filling system, softening and plasticizing system and other special compounding ag…

-

When using reclaimed rubber to produce rubber products, reasonable use of powder materials such as carbon black, silica, nano-calcium carbonate, nano-zinc oxide and nano-clay can not only ensure product quality…

-

For extruded rubber products, due to the effect of moisture in the compounding agent, these extruded rubber hoses, rubber strips and other finished products may generate air bubbles. At this time, it is necessa…

-

Common shock absorbing rubber products include rubber air spring, rubber shock pad, ship fender, etc. adding waste tire rubber powder in proportion to different products can effectively reduce the cost of raw m…

-

The amount of rubber oil used in reclaimed rubber products is not small, ranging from 5 or 6 parts to more than 40 parts, which directly affects the dispersion of fillers such as carbon black in reclaimed rubbe…

-

Rubber rollers are mostly composed of outer rubber, hard rubber layer, metal core, roller neck and ventilation holes. The rubber part has strict requirements on the rubber material used. The rational use of rec…

-

Adding an appropriate amount of vulcanization activator in the production process of reclaimed rubber products can significantly increase the activity of the accelerator, reduce the amount of accelerator, and s…

-

As the main raw material to reduce the cost of rubber products, reclaimed rubber can be used in the production of sponge rubber products to reduce costs; choosing a suitable antioxidant can significantly improv…

-

There are many types of release agents, most of which are substances with low surface tension, which can form a continuous release film among the polymer and the mold. They are divided into short-life and semi-…

-

In addition to the inner rubber layer, the outer rubber layer and the skeleton layer, the ordinary rubber hose with a multi-layer skeleton in the rubber tube also has a filler, that is, an intermediate rubber. …

-

When using reclaimed rubber to produce rubber products, the coupling agent can combine organic matter with non-compatible fillers and rubber matrix to improve the dispersibility of the filler in the reclaimed r…

-

In actual production, sulfur vulcanization systems are selected for most of the natural rubber blends. The diffusion effect of sulfur in different rubbers is different, and the combination of vulcanization acce…

-

When using EPDM rubber or reclaimed rubber to produce automobile engine bearings, bridge bearings and other shock-absorbing products, the type and amount of reinforcing agents directly affect the damping perfor…

-

Compared with ordinary calcium carbonate, the remarkable feature of activated calcium carbonate coated with an organic active agent is that it has stronger hydrophobic properties and better compatibility with r…

-

Tire tread rubber is generally processed from natural rubber / styrene butadiene rubber or natural rubber / CIS butadiene rubber / styrene butadiene rubber. Proper use of waste tire rubber powder in tread rubbe…