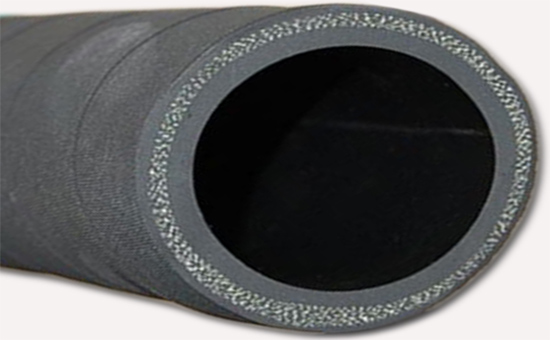

Rubber hoses are hollow flexible tubular rubber products used to transport various liquids, gases, powder or granular materials. According to their performance, they can be divided into ordinary hoses, medium-resistant hoses and special hoses. Among them, ordinary hoses with multi-layer skeletons In addition to the inner rubber layer, the outer rubber layer and the skeleton layer, the rubber tube also has a filler, that is, an intermediate rubber. In actual production, choosing appropriate rubber raw materials can further improve the comprehensive indicators of ordinary rubber hose fillers and reduce costs.

1. Ordinary hose filling glue function

Ordinary rubber hose intermediate glue mainly plays the role of filling, buffering, bonding the skeleton and glue layer in the entire hose, so that the hose is formed as a whole, reducing the friction fatigue and heat generation among the frame materials of the pipe body under the dynamic 2YLYY1027, and preventing the internal , The phenomenon of delamination among the outer rubber layer and the skeleton layer can be regarded as the protective layer of the inner rubber layer

2. Common rubber hose filling performance requirements

In actual production, ordinary rubber hose fillers require the rubber to have good adhesion, elasticity, softness and resistance to flexure. During vulcanization, the vulcanization rate should be matched with other rubber layers. The vulcanization permeability is strong, the initial sulfur point is slow, and the positive sulfur point should be slightly faster than the inner and outer rubber layers.

3. Ordinary hose filled rubber raw materials

The rubber content of ordinary rubber hose fillers is mostly controlled at about 35%. Generally, natural rubber is used as the main raw material. It can be used together with an appropriate amount of styrene butadiene rubber and butadiene rubber, or with a certain proportion of reclaimed rubber.

4. Ordinary hose filled rubber rubber accessories

The sulfur-accelerator system is generally selected for the vulcanization system of ordinary hose filling rubber, and the accelerator can be used together with thiazole accelerators and sulfenamide accelerators. Reinforcing filling system recommends that semi-reinforcing carbon black be combined with high wear-resistant carbon black, and the filler can use inorganic fillers such as calcium carbonate. In the hose filler softening system, petroleum-based liquid softeners such as heavy oil and asphalt can be used together with solid softeners; appropriately increase the amount of bonding softeners, such as coumarone, rosin, and RF and RH direct bonding systems.

In actual production, ordinary hose filling rubber can use reclaimed rubber (commonly used tire reclaimed rubber) to effectively reduce the cost of raw materials; choosing reclaimed rubber products that are close to the physical requirements of hose filling rubber can further increase regeneration while ensuring product quality. The amount of glue can reduce more raw material costs, and the editor will discuss relevant issues with you in detail later.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits