Case Description: Since June 2015, Tianjin customers have been using Okitsu's nitrile reclaimed rubber to produce oxygen pipes. From the perspective of performance, the Oxygen Oxygen products produced by this customer are mainly used for transporting industrial oxygen. The products are heat-resistant, anti-oxidant, and have a long service life. Long, by the customer's unanimous recommendation; from the cost point of view, Hongyun nitrile reclaimed rubber than nitrile rubber prices are low, can significantly reduce the cost of raw materials.

Case Study: In the current market, no matter what the competition is, there is fierce competition. There are also more and more low-priced products invading the market. They rely on price advantage to enter the customer's “heart”, and many good quality manufacturers are “coldly”. , Tianjin ** rubber products factory should also be the trend. Tianjin customers mainly produce industrial oxygen pipes. Nitrile rubber was used initially. However, due to the high price of nitrile rubber, the prices of the products are relatively high. At the beginning of the construction, there were fewer phenomena in the use of reclaimed rubber in the same industry. Product prices are not the same, relying on quality and quality to firmly stand the market. However, from the 15th year onwards, the customer's product sales have fallen in a monthly trend, which is an emergency for the manufacturer's responsible person.

After market research, there are more and more industrial oxygen pipe products available on the market. Many manufacturers are pricing their products much lower than their pricing. In particular, ** Rubber & Plastic Products Co., Ltd., which had just opened since the end of 2014, has a publicity theme of “ "The price is low," and a large proportion of customers are attracted to this company.

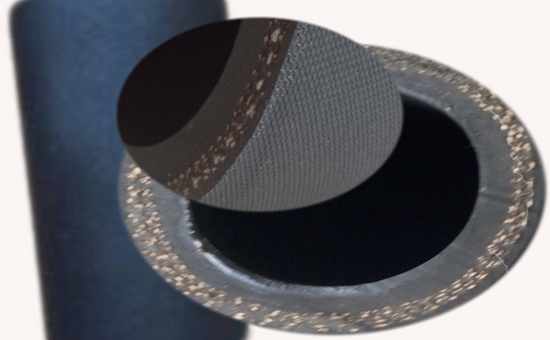

It turned out that this manufacturer used an nitrile regenerated rubber to produce oxygen pipes. Nitrile reclaimed rubber is a type of rubber processed from waste nitrile rubber products. It has the performance of nitrile rubber and its price is much lower than that of nitrile rubber. Therefore, the natural rubber produced from low-priced nitrile reclaimed rubber is naturally low in price. After all, the cost is here! Faced with this situation, the customer discovered that the nitrile reclaimed rubber used by the new company was an ordinary nitrile reclaimed rubber. Therefore, the quality of the industrial oxygen pipe produced was worth considering; the Tianjin customer decided to find a better quality Ding. Nitrile reclaimed rubber production of oxygen pipes, under the premise of reducing costs, from the quality with the opponent again.

From the perspective of Tianjin customers, they are fortunate because they have discovered reclaimed rubber from the very beginning. It took less than a month from trial to formal production. At the suggestion of Hongyun Engineer, the customer reduced the raw material cost of the oxygen pipe produced by the use of Hongyun Nitronitrile reclaimed rubber with a small amount of raw rubber by about 40%. The tested product has good heat resistance, flex resistance, and oxidation resistance. Performance and high tensile strength, flexibility, wear resistance, anti-aging, good performance, long service life.

Hongyun advantages: Hongyun nitrile reclaimed rubber products contain high amount of rubber, good feel elasticity, large coefficient of oil resistance, wear resistance, heat resistance, aging resistance, with good physical processing properties and chemical stability; Hongyun company has a professional rubber technology Engineers can formulate the most reasonable reclaimed rubber formula for customer needs.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits