Printing rubber rollers are rubber rollers used in printing machinery for embossing, ink mixing and ink transfer, generally processed with nitrile rubber, neoprene rubber or polyurethane rubber as the main rubber raw materials. Nitrile recycled rubber retains the basic performance characteristics of nitrile rubber, excellent oil resistance, good heat resistance, wear resistance, and good compatibility with nitrile rubber. What problems should be paid attention to when mixing printing rubber rollers with nitrile recycled rubber?

1. Performance requirements for printing rubber rollers

The printing rubber roller needs to be in contact with mineral oil, esters, and alcohol solvents for a long time, and the rubber material is required to have good oil resistance. When working, it needs to have good adhesion with the printing plate and paper to ensure uniform transfer of ink and low hardness of the adhesive. It has good wear resistance and reduces wear; It is required that the compound has low compression set and low heat generation to ensure the performance and life of the equipment.

2. Can nitrile recycled rubber produce printing rubber rollers?

Nitrile recycled adhesive has good oil resistance, wear resistance, elasticity and heat resistance: oil resistance can give the printing rubber roller the ability to resist the erosion of ink, cleaning agent and dampening fluid; wear resistance can reduce the surface wear E5LYY814 rubber rollers and maintain stable performance; Good elasticity can make the rubber roller quickly return to its original state after being pressed, ensuring uniform ink transfer. Heat resistance can ensure the stable performance of the rubber roller under the operating heat and extend the service life of the rubber roller. Therefore, nitrile recycled adhesive can be used in the production of printing rubber rollers.

3. Application skills of nitrile recycled rubber in printing rubber rollers

(1) Nitrile recycled rubber selection skills

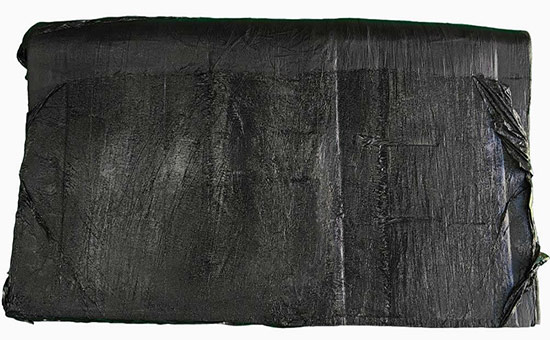

When using nitrile rubber as the main raw material printing rubber roller mixed with nitrile recycled rubber to reduce the cost of raw materials, it is recommended to choose NBR recycled rubber with high nitrile content, high fineness, and no impurities, which has higher mechanical strength, oil resistance, better elasticity, and smooth appearance of rubber rollers, which can replace more copies of nitrile rubber to produce printing rubber rollers, and effectively reduce the cost of raw materials under the premise of ensuring the performance of rubber rollers.

(2) Key points of printing rubber roller formula design with recycled rubber

When using nitrile recycled rubber in the printing rubber roller formula, it is necessary to control the proportion of nitrile recycled rubber and adjust the rubber formula appropriately. Generally, the doping ratio of nitrile recycled rubber in the printing rubber roller is controlled among 20% and 50%, and the sulfur-accelerator system (such as accelerator D) is used to improve the thermal conductivity of the printing rubber roller with zinc oxide. Use semi-reinforced carbon black or silica to reinforce, with filling talc, light calcium, etc.; use rosin, pinene resin and other tackification resins to further improve the self-adhesion of the adhesive.

(3) Key points of printing rubber roller production of nitrile recycled rubber

It is recommended to clean and dry the recycled rubber in advance to ensure that there are no impurities and moisture, and avoid affecting the surface quality of the rubber roller. During mixing, the mixing temperature and time are strictly controlled to ensure that the mixing agent is evenly dispersed. During calendering, the shape and size of the rubber roller are accurately controlled to ensure uniform and continuous compound material and avoid defects such as bubbles and sand holes. During vulcanization, adjust the vulcanization temperature and time according to the performance of nitrile rubber, nitrile recycled rubber and rubber rollers.

4. Nitrile rubber/nitrile recycled rubber is used in the reference formula for the production of printing rubber rollers

60 parts of nitrile rubber, 40 parts of nitrile recycled rubber, 5 parts of zinc oxide, 1 part of stearic acid, 1 part of anti-aging agent A, 1 part of anti-aging agent D, 35 parts of carbon black N660, 100 parts of light calcium carbonate, 10 parts of pine tar, 20 parts of dibutyl phthalate, 10 parts of liquid coumarone resin, 1 part of accelerator DM, 1 part of sulfur; A total of 285 copies.

When using nitrile recycled rubber to reduce the production cost of nitrile rubber printing rubber rolls, the mixing ratio and dosage requirements of nitrile recycled rubber are determined according to the physical property index of the recycled rubber, the performance requirements of the printing rubber roller and the cost budget, and we will continue to discuss related issues with you later.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits