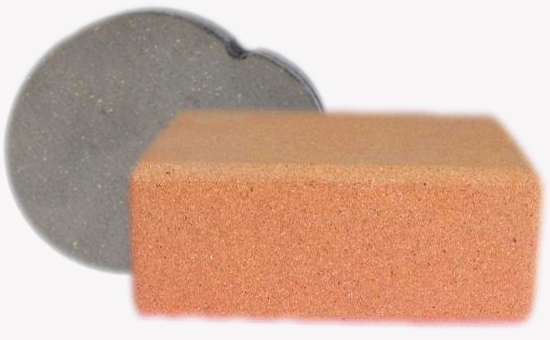

Case name: Shaanxi customers use nitrile reclaimed rubber to produce cork friction blocks

Case Overview: Since February 2016, Shaanxi Cork Products Co., Ltd. began to use Hongyun Nitrile Recycled Adhesive instead of raw rubber to produce softwood friction blocks. After testing, the cork friction block product specifications meet relevant standards to meet customer needs; and this At the same time, the replacement of raw materials did not result in a decline in the sales volume of softwood friction blocks, and the sales volume of cork friction blocks after a downward adjustment of a small part of the price continued to increase.

Raw material cost: The main raw materials of cork friction blocks are nitrile rubber and cork powder. Their ratio is approximately 2:3. The price of nitrile rubber is more than twice the price of nitrile reclaimed rubber, so high-quality nitrile reclaimed rubber is used. In place of nitrile rubber to produce softwood friction blocks, the cost of rubber raw materials can be reduced by at least half.

Performance Analysis: Nitrile reclaimed rubber is rubber processed from waste nitrile rubber products. High-quality nitrile reclaimed rubber products have excellent oil resistance and wear resistance, and can meet the performance requirements of softwood friction blocks for raw materials. The customer's softwood friction blocks produced by using Ford's nitrile reclaimed rubber instead of the original rubber have good oil resistance, heat insulation, high coefficient of friction, low wear rate and long service life; Hongyun nitrile reclaimed rubber has high fineness, good elasticity, and pull The stretcher has high strength and the softwood friction block has good bending strength, shockproof and sound absorption, and stable use performance.

Production process: When using nitrile rubber to produce softwood friction blocks, nitrile rubber must be fully plasticized before use; Hongyun nitrile rubber reclaimed rubber has been repeatedly processed in the production process, with good processing performance and high plasticity. The production of rubber products does not require smelting, which can save some of the electricity bills and reduce production costs.

Summary of case: According to Shaanxi customers, they used the Hongyun nitrile reclaimed rubber instead of the raw rubber to produce friction blocks with unexpected results. Although the product specifications of Hongyun nitrile reclaimed rubber cork blocks are inferior to those of nitrile nitrile rubber products, they can completely meet the needs of customers. Therefore, it was originally intended to reduce the cost of some raw materials and then lower the price of the products. Finally, customers in Shaanxi produced friction blocks. The cost of raw materials has been significantly reduced, the price of products has been reduced slightly, and the economic benefits have been significantly improved.

Xiaobian digression: The original nitrile reclaimed rubber can not only produce oil-resistant rubber products, but also can produce wear-resistant, shock-absorbing rubber products!

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits