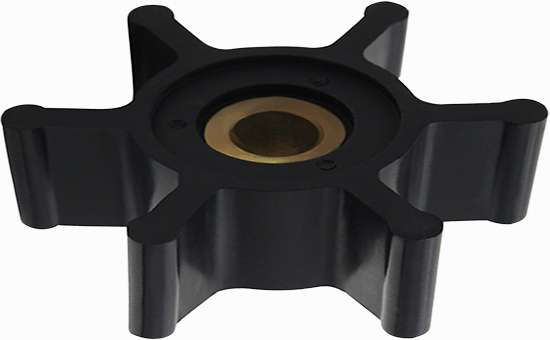

Rubber impeller is a blade-shaped rotating part made of rubber as the main raw material, which is used in various fluid power systems to transport liquids, regulate flow, enhance sealing, etc., and are widely used in industrial automation, environmental protection, ships, agriculture and other fields. Rubber impellers are used in different environments, and different varieties of rubber need to be used for production. Nitrile rubber has excellent oil resistance and wear resistance, which is an ideal raw material for the production of rubber impellers; The price of nitrile reclaimed rubber is much lower than that of nitrile rubber, which can replace part of the original rubber to produce rubber impellers and reduce costs.

1. Rubber impeller performance requirements

Rubber impellers need to have excellent oil and chemical resistance, and resist long-term contact with oils, acids, alkalis, and solvents to avoid swelling or degradation. The rubber impeller requires that the rubber material used has good elasticity, flexibility, wear resistance, sufficient tensile strength and tear strength, low compression set, etc., to reduce the damage caused by sudden impact load, resist the long-term friction and collision of particulate matter in the fluid, prevent the rubber impeller from breaking or damage and liquid leakage during high-speed operation, and prolong the service life.

2. The advantages of using nitrile reclaimed rubber for nitrile rubber impellers

Nitrile reclaimed rubber is made of waste nitrile rubber products as raw materials, and is made by crushing, desulfurization, kneading, and unloading, which retains the basic performance characteristics of nitrile rubber, has a large oil resistance coefficient, and can resist the erosion of mineral oil, fuel oil and other media; Good wear resistance and heat resistance, the price is much lower than that of nitrile rubber, and it can be used alone or combined with nitrile rubber in any proportion to produce rubber impellers, effectively reducing the cost of raw materials. The rubber impeller produced by nitrile rubber/nitrile reclaimed rubber and rubber is suitable for oil pumps, oil conveying equipment, etc.

3. Nitrile rubber/nitrile reclaimed rubber is used to produce rubber impeller vulcanization formula

75 parts of nitrile rubber, 25 parts of nitrile reclaimed rubber, 5 parts of zinc oxide, 1 part of stearic acid, 1 part of antioxidant 4010NA, 1 part of antioxidant MB, 0.5 parts of antioxidant H, 40 parts of carbon black N330, 25 parts of spray carbon black, 14 parts of dibutyl sebacate, 2 parts of dioctyl phthalate, 1.2 parts of accelerator DM, 1.4 parts of accelerator TMTD, 0.5 parts of sulfur; Total 192.6 copies.

4. Key points of the formula design of rubber impeller for the production of nitrile reclaimed rubber

(1) Reclaimed rubber selection: when the rubber impeller uses nitrile reclaimed rubber to reduce costs, it is necessary to choose the appropriate nitrile reclaimed rubber according to its use requirements, if the oil resistance is very high, it is recommended to choose reclaimed rubber with high acrylonitrile content; When there are certain requirements for cold resistance, it can be used in combination with an appropriate amount of butadiene rubber; The mixing ratio of nitrile reclaimed rubber is controlled at 30%-60%, which reduces the cost on the premise of ensuring the performance of the rubber impeller.

(2) Selection of rubber additives: sulfur-accelerator system can be used for the production of rubber impellers by nitrile reclaimed rubber, and the vulcanization system with low sulfur dosage can endow the vulcanized rubber with E4LYY1218 thermal and oxidative aging resistance, compression set resistance, and less dynamic heat generation; The use of high wear-resistant carbon black reinforcement can improve the mechanical strength and wear resistance of the rubber impeller, and the processing performance can be improved with spray carbon black. DBP is commonly used as a plasticizer to improve the processing performance and viscosity of the rubber compound, and reasonably control the amount of plasticizer.

When using nitrile reclaimed rubber to reduce the production cost of rubber impellers, it is not only necessary to select the appropriate nitrile reclaimed rubber and reasonably design the rubber impeller formula containing reclaimed rubber, but also to properly adjust the production process conditions to ensure that the reclaimed rubber is mixed evenly with various compounding agents to avoid performance differences caused by uneven mixing; According to the shape and size of the rubber impeller, select the appropriate molding method, and strictly control the process parameters such as molding temperature, pressure and time; The editor will continue to discuss related issues with you in the future.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits