Natural Rubber Encyclopedia

-

The secondary-brand natural rubber has good elasticity and high mechanical strength, and its price is much lower than that of the main-brand natural rubber. Can it be used as a substitute for natural rubber in …

-

Styrene-butadiene superfine reclaimed rubber can be used alone or in combination with natural rubber and styrene-butadiene rubber to produce various rubber products, reducing production costs by about 20%. How …

-

Natural rubber has high mechanical strength, good elasticity, low creep, excellent fatigue resistance, and outstanding cold resistance, making it an ideal material for producing bridge rubber bearings. However,…

-

Secondary grade natural rubber and secondary grade styrene-butadiene rubber each have their own advantages and disadvantages in terms of performance. By fully understanding the differences among the two, one ca…

-

Natural rubber sponge washers have good elasticity, softness, flex resistance, and heat insulation properties. Which types of reclaimed rubber can be used to replace natural rubber in producing sponge washers? …

-

Both by-product natural rubber and regenerated rubber from natural latex possess the basic properties of natural rubber and are much cheaper than natural rubber, making them the main raw materials for replacing…

-

Tire repair glue is generally made from natural rubber or synthetic rubber as the base material. By reasonably blending in reclaimed rubber, the raw material costs can be effectively reduced while ensuring the …

-

The acid resistant rubber hose is mainly used to transport acid medium and can be used in acid environment for a long time. When using natural rubber as the main raw material to prepare acid resistant rubber ho…

-

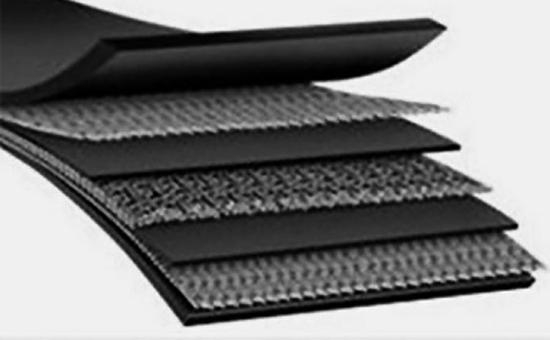

The covering rubber of the general purpose fabric core conveyor belt requires that the covering rubber has high tensile strength, elasticity, wear resistance, tear resistance, heat resistance and ozone resistan…

-

Natural rubber has the characteristics of good elasticity, high strength, tear resistance, and wear resistance, and is an ideal raw material for the production of bicycle pedal glue. Which low-cost rubber raw m…

-

The price of natural rubber on the market fluctuates greatly, so many rubber product manufacturers want to use low-priced and stable recycled rubber to replace some natural rubber, and the cost is easier to con…

-

The use of recycled rubber to reduce the production cost of automotive fan belt must be selected according to the specific performance needs of each layer of the fan belt.

-

Ordinary rubber V-belt compression layer glue is located at the bottom of the V-belt, supports the V-belt core layer, plays the role of increasing the V-belt section, increasing the friction surface of the V-be…

-

Natural rubber has good elasticity, high mechanical strength, wear resistance and flexural resistance, and is an ideal raw material for the production of rubber diaphragm for automobile brake chambers; However,…

-

The chemical structure of the sub-brand styrene-butadiene rubber is basically the same as that of genuine styrene-butadiene rubber, and the price is much lower, and it can be used alone or in combination with g…

-

The bead triangle rubber core is generally processed with natural rubber as the main raw material, and a large amount of reclaimed rubber is mixed with a reasonable design of the triangle rubber core formula, w…

-

Rubber bearings for trailer vehicles require the rubber layer to have good bearing capacity, compactness, wear resistance and aging resistance, bonding firmness, etc., generally processed with natural rubber as…

-

The high price of natural rubber and the large price fluctuation are obvious to all, the appropriate amount of reclaimed rubber and reasonable design of rubber formula can not only reduce the cost of raw materi…

-

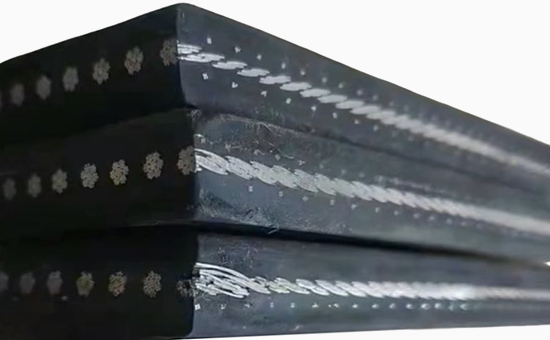

Ordinary steel wire rope core conveyor belt is a conveyor belt with a number of wire ropes arranged longitudinally at a specified spacing as the belt core tensile body, and the sub-brand natural rubber has the …

-

The price of natural rubber is high and fluctuates greatly, and the aging resistance is not good, so many automobile shock absorber manufacturers have begun to mix reclaimed rubber in natural rubber vehicle sho…