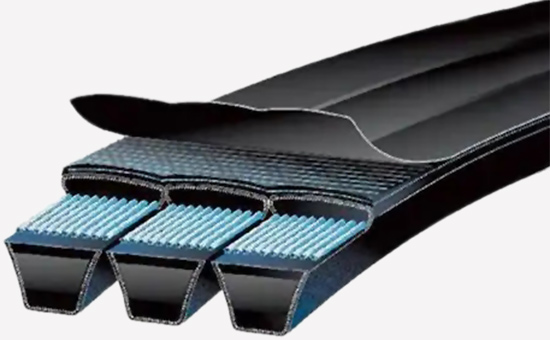

Ordinary rubber V-belt is a kind of rubber products for mechanical transmission with trapezoidal cross-section and V-shaped on both sides, which is generally composed of compression layer, extension layer, cord layer and wrapping layer, and the performance requirements of different rubber layers are different. In actual production, natural rubber has good elasticity, wear resistance and anti-aging properties, and is widely used in the preparation of rubber compounds for each rubber layer of the V-belt.

1. Ordinary rubber V-belt compression layer glue mixed with reclaimed rubber vulcanization formula

75 parts of natural rubber, 25 parts of recycled rubber, 2.5 parts of zinc oxide, 2 parts of stearic acid, 1 part of antioxidant A, 1 part of antioxidant D, 30 parts of carbon black N774, 15 parts of mixed carbon black, 30 parts of light calcium carbonate, 3 parts of coumaron resin, 4 parts of softened heavy oil, 0.5 parts of accelerator DM, 0.8 parts of accelerator CZ, 2 parts of sulfur; Total 191.8 copies.

2. Ordinary rubber V-belt stretch layer rubber is mixed with reclaimed rubber vulcanization formula

80 parts of natural rubber, 20 parts of recycled rubber, 2.5 parts of zinc oxide, 2 parts of stearic acid, 1 part of antioxidant A, 1 part of antioxidant D, 42 parts of carbon black N774, 33 parts of mixed carbon black, 17 parts of light calcium carbonate, 3.3 parts of coumaron resin, 3.3 parts of dibutyl phthalate, 0.5 parts of accelerator DM, 0.85 parts of accelerator CZ, 2.15 parts of sulfur; Total 208.6 copies.

3. Ordinary rubber V-belt wrapping cloth layer rubber mixed with reclaimed rubber vulcanization formula

75 parts of natural rubber, 25 parts of recycled rubber, 4 parts of zinc oxide, 1.9 parts of stearic acid, 1 part of antioxidant A, 1 part of antioxidant D, 15 parts of carbon black N774, 22 parts of light calcium carbonate, 3 parts of coumarone resin, 2.5 parts of softened heavy oil, 1.1 parts of accelerator CZ, 2 parts of sulfur; Total 153.5 copies.

Ordinary rubber V-belt compression layer rubber requires the rubber compound to have good heat resistance, flexural resistance, small heat generation, small compression deformation, good adhesive performance and sufficient hardness; The extension layer rubber requires the rubber compound to have good fatigue E4LYY828 resistance, large elasticity, small deformation and high tensile stress; The coating layer glue requires the rubber material to have certain adhesion and wear resistance, heat resistance, aging resistance, flexural resistance and other properties, and has good adhesion performance with the cloth layer. When using reclaimed rubber to reduce the production cost of natural rubber V-belt, we must choose the appropriate reclaimed rubber according to the specific needs of each rubber layer, and reasonably design the formula of each component of the rubber V-belt containing reclaimed rubber.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits