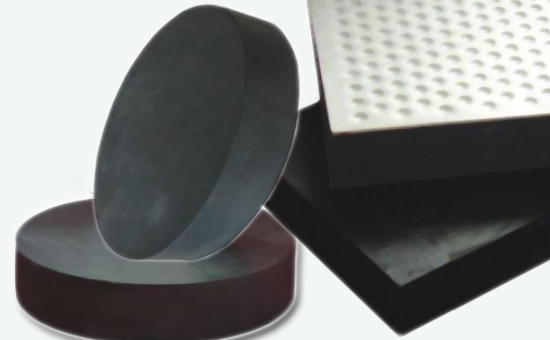

Case Background: Compared to various types of metal bearings, rubber bridge bearings are simpler in structure, easier to process, easier to install, more flexible, and have a much lower cost, and are therefore more popular. The main raw materials of rubber bridge bearings are neoprene rubber, natural rubber and EPDM rubber. However, the rubber bearings produced in this way are costly. Many manufacturers began to use low-priced rubber materials to produce rubber bridge bearings. Fortunately, there are many customers who produce bridge bearings. Among them, a local manufacturer of bridge bearings in Hengshui is a representative customer.

Case name: Black composite natural rubber production rubber bridge bearings reduce costs

Case Description: Prior to the use of Hongyun Black Composite Natural Rubber, the customer used other manufacturers' reclaimed rubber to produce bridge bearings, the production cost was very low, and good economic benefits were achieved in the short term. However, after a period of time, users have responded to the problem that the aging performance of the bridge bearings is poor, there is an abnormal displacement and some degree of damage and other issues, some users began to request a return of compensation. In order to improve the quality of the product, the customer decided to use natural rubber to produce bridge bearings, but it also encountered a problem of high costs and production was once in a stalemate.

Case development: It was a coincidence that when the client was overwhelmed, he listened to a friend on the wine table and talked about the reincarnation of the game. He quietly remembered it. On the third day, they took their two types of bridge bearings made from reclaimed rubber and natural rubber to the Hongyun Headquarters.

Hongyun engineers carefully compared the differences between the two products, and inquired about the basic requirements of some products as well as the problems that occurred in the previous period. We recommend customers to use black composite natural rubber imported from Vietnam that has a lower price than natural rubber but is higher than reclaimed rubber. In the beginning, customers were too expensive to be afraid that the manufactured products were not up to the standard. Our sales staff took out the relevant test reports and some samples of the products, hoping that they could try.

In the end, the customer used the advantages of large-capacity, low-distortion, and good buffering performance of the bridge bearings produced by the Hongyun Black Composite natural rubber, which was qualitatively superior to the previous reclaimed rubber bridge bearings; it was produced with natural rubber. Compared with bridge bearings, there is a slight difference in the indicators, but it can fully meet the needs of users, the most important is to reduce the production cost of about 35%, it can be said to achieve "high quality" and "low cost" coexist.

Experience summary: Hongyun imported black composite natural rubber from Vietnam is made of floor glue and glue glue as the main raw materials. The product is environmentally friendly, wear-resistant, free of impurities, small in specific gravity, high in tensile strength, and has good hand elasticity. Natural rubber produces a variety of extruded, molded rubber products. If you want high quality, you'd better use the original glue; if you want to reduce the cost, try reclaiming glue; both want, or use good quality reclaimed rubber, plus a reasonable formula, or consider a variety of composite natural Plastic, floor glue it! Opportunities are often easily caught by people who are interested. You, are you?

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits