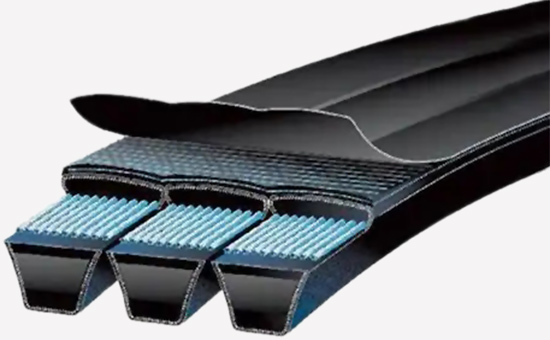

Ordinary rubber V-belts are required to have good dynamic properties such as high resilience, low heat generation, good heat resistance, flexural rupture resistance, oil resistance and ozone resistance; The compression layer glue is located at the bottom of the V-belt, supports the core layer of the V-belt, and plays the role of increasing the V-belt section, increasing the friction surface among the V-belt and the sheave and improving the transmission efficiency.

1. Performance requirements and formula design points of ordinary rubber V belt compression layer

(1) Performance requirements: the compression layer of ordinary rubber V-belt will be periodically compressed when working in V-belt, and the heat generation is large, which requires the rubber material used to be heat-resistant, small heat-generated, flexural-resistant, with sufficient hardness, small compression deformation, and good adhesion with the cord.

(2) Formula design

Ordinary rubber V-belt compression layer rubber mostly uses natural rubber, or used in combination with styrene-butadiene rubber and neoprene, and the glue content is controlled at about 40% when mixing reclaimed rubber to produce V-belt compression layer glue; Rubber V with compression layer rubber can choose black latex reclaimed rubber or tire reclaimed rubber. The V-band compression layer glue containing reclaimed rubber can be reinforced with carbon black, and the high wear-resistant carbon black can be used in combination with other carbon blacks; The sulfur-accelerator system is commonly used in the vulcanization system, and the accelerator M/DM or CZ/NOBS is used together, and the amount of zinc oxide is appropriately increased to improve the thermal conductivity of the rubber compound; In order to enhance the wear resistance and transverse rigidity of the V-belt compression layer compound, 10-20 parts of staple fiber can be used in an appropriate amount.

When the formula containing styrene-butadiene rubber adopts medium and super wear-resistant furnace black to improve the strength, the softening plasticizer should be used as little as possible, and the appropriate amount of engine oil can be added to improve the elasticity of the rubber.

2. Ordinary rubber V-belt compression layer rubber mixed with reclaimed rubber vulcanization formula

(1) Natural rubber/reclaimed rubber is used to produce rubber V-belt compression layer rubber vulcanization formula

75 parts of natural rubber, 25 parts of recycled rubber, 2.5 parts of zinc oxide, 2 parts of stearic acid, 0.75 parts of antioxidant A, 0.75 parts of antioxidant D, 32 parts of carbon black N774, 16 parts of mixed carbon black, 30 parts of light calcium carbonate, 3 parts of coumaron resin, 4 parts of softened heavy oil, 0.45 parts of accelerator DM, 0.75 parts of accelerator CZ, 2 parts of sulfur; Total 194.2 copies.

(2) Natural rubber/styrene-butadiene rubber/reclaimed rubber is used to produce rubber V-belt compression layer rubber vulcanization formula

40 parts of natural rubber, 40 parts of styrene-butadiene rubber, 20 parts of recycled rubber, 5 parts of zinc oxide, 2 parts of stearic acid, 0.8 parts of antioxidant A, 0.8 parts of antioxidant D, 24 parts of carbon black N330, 16 parts of carbon black N774, 16 parts of clay, 25 parts of light calcium carbonate, 3.2 parts of pine tar, 3.2 parts of coumarone resin, 1.6 parts of asphalt, 0.5 parts of accelerator M, 0.35 parts of accelerator DM, 0.35 parts of accelerator D, 2.2 parts of sulfur; Total 201 copies.

(3) Natural rubber/neoprene/reclaimed rubber and vulcanization formula for the production of rubber V belt compression layer

55 parts of natural rubber, 25 parts of neoprene, 20 parts of recycled rubber, 7.5 parts of zinc oxide, 2.1 parts of stearic acid, 1.6 parts of antioxidant D, 13 parts of carbon black N330, 25 parts of carbon black N774, 32 parts of clay, 22 parts of light calcium carbonate, 1 part of magnesium oxide, 1.7 parts of pine tar, 1.7 parts of coumaron resin, 0.5 parts of accelerator DM, 1.5 parts of sulfur; Total 209.6 copies.

Rubber V-belt is mainly composed of compression layer, elongation layer, cord layer, wrapping layer, etc., different parts of the performance requirements are different, rubber V-belt manufacturers can choose the appropriate variety of reclaimed rubber according to the specific needs of each rubber layer E5LYY228, reasonably determine the proportion of reclaimed rubber and appropriately adjust the production formula and production process parameters, effectively reduce the cost of raw materials and production energy consumption under the premise of ensuring the performance and life of the rubber V-belt.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits