Sub-brand natural rubber is a secondary product in the process of natural rubber processing due to raw material fluctuations, production process deviations, equipment failures and other factors that produce color and index slightly not up to standard, with the basic performance characteristics of natural rubber, high mechanical strength, good elasticity, wear resistance, low temperature resistance, can replace natural rubber to produce various types of rubber products, and effectively reduce the cost of raw rubber under the premise of ensuring the performance of finished products.

1. The common application of sub-brand natural rubber in the rubber products industry

(1) Tire processing

Tires are one of the important application fields of sub-brand natural rubber, which can reduce the cost of raw rubber on the premise of ensuring the driving comfort and safety of tires. For example, tire tread rubber requires good wear resistance, tear resistance and grip, and sub-brand natural rubber can be used with natural rubber, styrene-butadiene rubber, and butadiene rubber to produce tire tread rubber; Tire sidewall rubber requires the rubber compound to have good flex resistance and certain strength, and the sub-brand natural rubber can meet the basic needs of the sidewall rubber. Sub-brand natural rubber can also be used for tire carcass, bead and other parts of the processing.

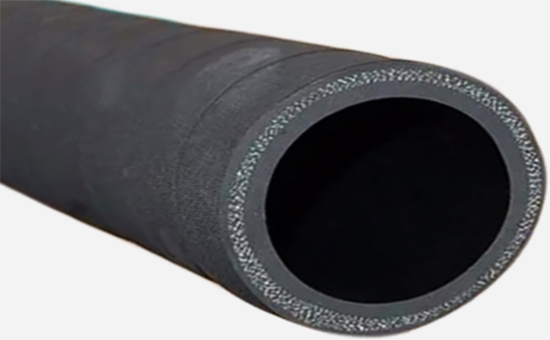

(2) Industrial rubber

Sub-brand natural rubber can be used in the production of industrial rubber products, such as hoses, tapes, seals, etc. Ordinary water hoses and gas hoses require good elasticity and certain strength of the rubber compound, and can be mixed with sub-brand natural rubber in a high proportion. When sub-brand natural rubber is used in ordinary rubber conveyor belts E4LYY1029 and V-belts, choosing the appropriate reinforcing agent can further improve the wear resistance and fatigue resistance of the belt. Rubber seals such as sealing rings, sealing gaskets, etc. require rubber materials to have good sealing, medium resistance and aging resistance, and sub-brand natural rubber has a certain resistance to general oil, water, air and other media, which can be used to prepare ordinary rubber sealing products.

(3) Daily necessities

Sub-brand natural rubber can be used in the production of rubber products used in daily life, such as rubber soles, rubber toys, rubber handle sheaths, rubber floors, etc. Rubber soles require rubber materials to have good elasticity, abrasion resistance and anti-slip properties, and the good elasticity and abrasion resistance of sub-brand natural rubber can meet the basic needs of rubber soles. When using sub-brand natural rubber to produce rubber toys such as rubber balls, the light-colored sub-brand natural rubber is light in color, easy to match colors, and can produce more color rubber toys, requiring the sub-brand natural rubber to meet the relevant safety standards.

2. Techniques for using sub-brand natural rubber in the production of rubber products

The use of sub-brand natural rubber to produce rubber products needs to choose the right products according to the actual needs of the products, such as rubber products with high tensile strength requirements, it is recommended to use sub-brand natural rubber with low impurity content and relatively good physical and mechanical properties. Sub-brand natural rubber can be used in combination with styrene-butadiene rubber, butadiene rubber and other synthetic rubbers to further improve the aging resistance and wear resistance of products; Reasonable selection of reinforcing agent and vulcanizing agent to improve the physical and mechanical properties of sub-brand natural rubber products.

In the production of sub-brand natural rubber products, it is also necessary to appropriately adjust the production process according to the characteristics of sub-brand rubber, such as appropriately extending the mixing time during mixing to ensure that the compounding agent is fully mixed with rubber; Control the vulcanization parameters, such as vulcanization temperature and vulcanization time, to improve the quality of vulcanized rubber; Strengthen the quality control of each process, timely test the performance indicators of the product, and ensure that the product quality meets the requirements.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits