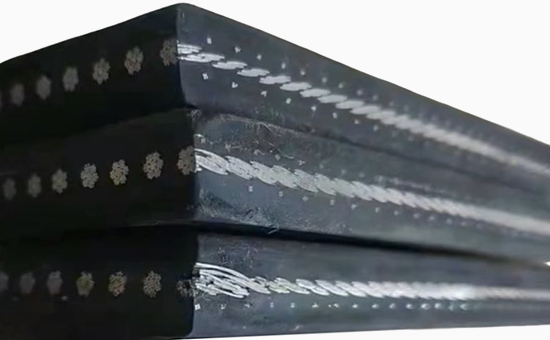

Ordinary wire rope core conveyor belt is a conveyor belt with a number of wire ropes arranged longitudinally at a specified interval as the core tensile body, which is composed of core rubber, wire rope, covering layer and edge rubber, which has the performance characteristics of small elongation, high tensile strength, flexural resistance, impact resistance, etc., and is widely used in coal, mining, metallurgy, electric power, chemical industry and other fields to transport materials. The sub-brand natural rubber has the basic performance characteristics of natural rubber, which can replace the steel wire rope core conveyor belt produced by natural rubber and reduce the cost of raw materials.

1. Wire rope conveyor belt with sub-brand natural rubber selection skills

Ordinary wire rope conveyor belts generally use natural rubber as the main raw material to meet the performance requirements of conveyor belts. When using sub-brand natural rubber to reduce the raw material cost of ordinary wire rope conveyor belt, the appropriate sub-brand natural rubber can be E4LYY1128 selected according to the specific physical needs of the conveyor belt, and the mixing ratio of sub-brand natural rubber can be reasonably determined, or it can be used in combination with genuine natural rubber and styrene-butadiene rubber to further improve the processing performance of rubber and improve the tensile strength, wear resistance and aging resistance of the wire rope conveyor belt.

2. Sub-brand natural rubber production wire rope core conveyor belt formula design

(1) Covering glue: The covering rubber of the steel wire rope core conveyor belt is required to have good wear resistance, impact resistance, fatigue resistance, aging resistance and tear resistance. Sub-brand natural rubber can be used alone or in combination with genuine natural rubber and styrene-butadiene rubber; High abrasion resistance, medium and super wear-resistant carbon black reinforcement, appropriate use of gas-mixed carbon black, semi-reinforcing carbon black, rubber content is recommended to control more than 50%.

(2) Rope core rubber: The rope core rubber material of the steel wire rope core conveyor belt requires good adhesion and flexural fatigue resistance with the steel wire, and the sub-brand natural rubber can be used in combination with genuine natural rubber, styrene-butadiene rubber, or with butadiene rubber; High wear-resistant furnace black, medium super wear-resistant furnace black, mixed carbon black are used alone or in combination; It is recommended that the copper-plated steel wire bonding system should be mainly based on the m-methyl white system, and a small amount of cobalt salt adhesive can be used. It is recommended that the galvanized steel wire bonding system should be mainly cobalt salt binder, and a small amount of m-methyl white system can be used.

3. Vulcanization formula for sub-brand natural rubber production wire rope core conveyor belt

(1) Natural rubber/sub-brand natural rubber production wire rope core covering rubber vulcanization formula

50 parts of natural rubber, 50 parts of sub-brand natural rubber, 5 parts of zinc oxide, 3 parts of stearic acid, 1 part of antioxidant A, 1 part of antioxidant D, 1 part of paraffin, 50 parts of mixed carbon black, 6 parts of pine tar, 4 parts of heavy oil, 0.7 parts of accelerator M, 0.8 parts of accelerator DM, 2.5 parts of sulfur; 175 copies.

(2) Sub-brand natural rubber/styrene-butadiene rubber production wire rope core covering rubber vulcanization formula

50 parts of sub-brand natural rubber, 50 parts of styrene-butadiene rubber, 5 parts of zinc oxide, 2.5 parts of stearic acid, 1 part of antioxidant A, 1 part of antioxidant D, 1.5 parts of paraffin, 30 parts of carbon black N220, 20 parts of mixed carbon black, 10 parts of coumarone resin, 6 parts of engine oil, 1 part of accelerator M, 1 part of accelerator DM, 2 parts of sulfur; Total 181 copies.

(3) Natural rubber/sub-brand natural rubber/styrene-butadiene rubber production wire rope core rope core rubber vulcanization formula

30 parts of natural rubber, 40 parts of sub-brand natural rubber, 30 parts of styrene-butadiene rubber, 8 parts of zinc oxide, 2 parts of stearic acid, 1 part of antioxidant BLE, 1 part of antioxidant SP, 45 parts of carbon black N330, 19 parts of silica, 6 parts of cobalt naphthenate, 1 part of adhesive A, 1.5 parts of adhesive RE, 9 parts of heavy oil, 1.4 parts of accelerator NOBS, 3.1 parts of sulfur; Total 198 copies.

When using sub-brand natural rubber to produce different rubber layers of wire rope conveyor belts, it is necessary to choose the appropriate sub-brand natural rubber according to actual needs, and if necessary, you can also use sub-brand styrene-butadiene rubber, high-strength tire reclaimed rubber, etc., so as to effectively reduce the cost of raw materials and save industrial and electrical costs on the premise of ensuring the performance of the conveyor belt.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits