When producing composite products that require reinforcement with skeletal materials, such as hoses and tapes, using recycled rubber as the main raw material, it is essential to ensure a strong adhesion among the rubber compound and the skeletal materials. The level of adhesion directly affects the performance and service life of recycled rubber products. In actual production, the adhesive systems commonly used in recycled rubber product factories are mainly divided into two types: the m-phenylene diamine adhesive system and the cobalt salt adhesive system.

1. m-Phenylene diamine adhesive system

The Jiajia-Bai system refers to the HRH or RFS system. "Jia" refers to resorcinol, which acts as a methylene acceptor (adhesives RS, RE, RS-11, RK); "Bai" refers to formaldehyde, which is usually a substance that can release E5LYY522 formaldehyde at vulcanization temperatures, acting as a methylene donor (adhesives A, RA, H30); "White" refers to white carbon black, i.e., silica, which is the active material. The combination of these three materials can produce a synergistic effect, creating strong adhesion among regenerated rubber and the reinforcing material.

When using reclaimed rubber to produce rubber products containing skeletal materials, both the methylene donor and acceptor can be directly added to the rubber compound during mixing, with the methylene donor used in the range of 1.5-2.5 parts and the acceptor in the range of 2.5-3.8 parts; the adhesive containing both the donor and acceptor in its molecular structure is used in the range of 1.5-5.0 parts.

There are two methods for using adhesives RP and RP-L on polyester canvases or ropes.

① Single-dip method: Prepare a 20% solution of RP (or RP-L) containing NH4OH and then mix it with m-phenylene impregnated latex for use;

②Double-dip method: First, carry out the first dip using a solution containing RP or RP-L, and then perform the second dip using m-phenylene latex solution. Generally, the double-dip method is more effective, but if handled properly, the single-dip method can achieve adhesion equivalent to that of the double-dip method.

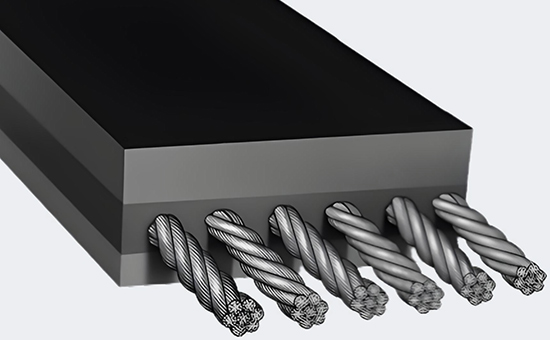

2. Cobalt salt system adhesive

Adding cobalt salts to recycled rubber compounds can improve the adhesion among reclaimed rubber and metal materials. The cobalt salt adhesion system can be directly added to the compound during mixing, used alone or in combination with the m-phenylene diamine-based adhesion system, with a general dosage of 0.15-1.0 parts. When using cobalt salt-based adhesives in recycled rubber products, the following points should be noted: cobalt can catalyze the aging of rubber, so the amount in the compound should not be excessive; storage should be away from fire and heat sources, and during transportation, protection from sun and rain is required.

① When cobalt salts are added to the compound, they form accelerator-sulfur-cobalt salt complexes that promote the formation of a copper sulfide layer on the surface of brass-coated steel cords, improving the adhesion among rubber and steel wires.

②The cobalt salt system is highly sensitive to the type of accelerator used and is usually preferred with sulfenamide-type accelerators.

③The cobalt salt system can produce a synergistic effect with the m-phenylene diamine system; using both systems together can achieve higher adhesion levels and overcome the drawbacks of each system when used alone.

④Among various cobalt salts, cobalt carboxyborane has the best overall performance. In its molecule, cobalt and boron are connected to organic components through oxygen. Because the boron-oxygen-cobalt bond is weak, cobalt can be quickly released from the molecule, greatly enhancing its activity. The adhesive properties of other cobalt salts do not differ significantly.

When producing rubber products containing skeletal materials using recycled rubber, it is necessary to choose an appropriate bonding system according to specific performance requirements; later, the editor will continue to share with you the specific applications of bonding systems in different rubber products.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits