Recently, a customer in Shandong has reported that the steam plug produced by EPDM reclaimed rubber has a problem of blooming. This kind of problem has not occurred before using the same kind of reclaimed rubber. For the first time, the customer chose our EPDM reclaimed rubber for the first time in August 2020. Yang Gong of the technical department provided the customer with the corresponding formula. This formula can be used by many ethylene-propylene rubber customers with only a small amount of adjustment to produce high-quality EPDM rubber. For ethylene-propylene products, there has never been a problem of frosting during use. Inquiring about similar customers of the same batch of EPDM reclaimed rubber, the reply can be used normally after telephone communication. Where is the problem?

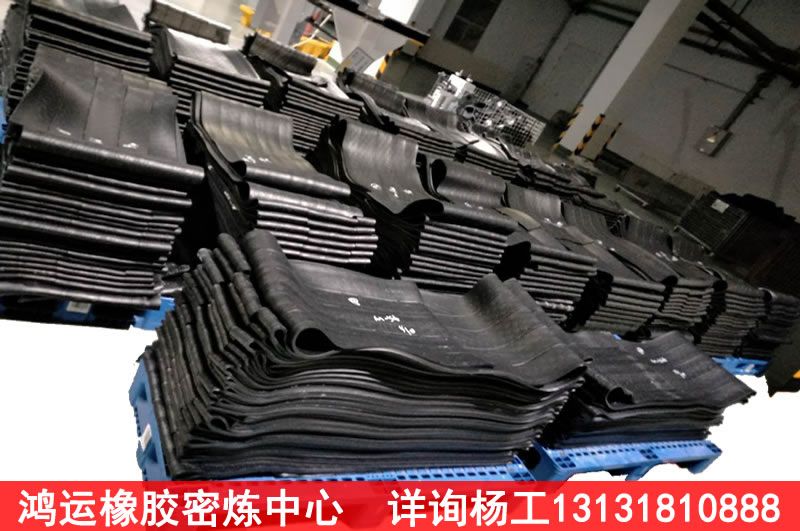

After a detailed comparison of customer formulas, investigation of changes in auxiliary materials and customer feedback on similar products, it was finally concluded that the problem occurred in the mixing process. I also remind friends here that you need to be careful when changing rubber mixers. It may be a good formula to a different person. In the hands, the result is completely different. The final troubleshooting problem is summarized as follows, and customers with similar experience can also learn from it.

Factors such as formula, rubber raw materials, auxiliaries, auxiliary materials, and mixing process will affect the quality of the rubber compound (uneven dispersion of the compounding agent, frost spray, scorch). Some problems in the mixing process can be directly observed visually.

1. Uneven dispersion of compounding agents

Particle additives or agglomeration additives can be seen on the surface of the mixed rubber, and there are compound particles of different sizes on the cross section after the film is cut. The cross-section of the evenly mixed ethylene-propylene reclaimed rubber should be smooth and bright. Excluding the factors such as damping of additives or expired failure, such as uneven dispersion of additives, if the phenomenon of uneven dispersion of additives cannot be improved after repeated refining, this batch of mixed rubber is really unusable. When kneading rubber, you can cut small pieces of two films from both ends and the middle of the roller, and observe the dispersion of additives to determine the length of kneading.

2. Frosting when the rubber compound is parked

The white substance precipitated on the surface of the mixed rubber when it was parked to restore the cross-linking property. Except for the use of the proportion of the formulation design aids, the most likely cause was the wrong order of adding the additives during the mixing process, or the mixing aids did not disperse and agglomerate. caused. In the process of mixing rubber, it is necessary to strictly control the addition sequence of additives in accordance with the formula requirements, and carefully observe the dispersion of additives in the rubber compound.

3. Scorch during the mixing process

The scorch during the mixing process is divided into two categories. One is the scorch during the mixing process of the Banbury mixer. The slightly scorched surface or partially elastic cooked rubber particles can be solved by the thin pass of the open mill; Burning will cause the rubber material to disperse into powder or block, which cannot be formed, and the mixed rubber is basically scrapped. The second type is scorch during the rubber mixing process of the open mill.

The most likely cause of scorch during the mixing process of the mixer is that the temperature is too high, the temperature of the mixer reaches more than 100 degrees, the second is the addition of a vulcanizing agent accelerator in advance, and the third is that the amount of plasticizer is too small or the type is wrong. In addition to scorch during the rubber mixing process of the open mill, the temperature factor is removed, and the simultaneous addition of vulcanizing agent and accelerator is also prone to scorch. In addition, the amount of glue loaded is too large, and the load of the open mill is too large, which will cause the temperature of the roller to rise.

4. The hardness of the rubber compound fluctuates greatly

Reclaimed rubber with the same hardness uses the same auxiliary materials, and the hardness of the mixed rubber of different manufacturers is often different, and some are even far from each other. The main reason is the uneven mixing of the rubber compound and the poor dispersion of the additives. Sometimes inaccurate weighing will also cause fluctuations in the hardness of the rubber compound. For example, if the amount of vulcanizing agent, accelerator, and carbon black is too large, the hardness of the rubber compound will increase; Add less calcium carbonate, etc., and the hardness of the rubber compound becomes smaller. At the same time, the mixing time and the number of roll passes are also influencing factors. If the mixing time is too long, in addition to the decrease in the hardness of the rubber compound, the tensile strength will decrease, the elongation at break will increase, and the aging resistance will decrease; if the mixing time is too short, the compound will become hard.

Rubber refining is a very basic position, and must be familiar with various raw rubber and raw materials, such as: magnesium oxide, nitric oxide and calcium hydroxide; high wear-resistant carbon black, fast-extruded carbon black and semi-reinforced carbon black, etc. . Not only need to have a solid ability to distinguish, but also need to be careful and conscientious, with a rigorous and responsible work attitude to do a good job of rubber mixing, so that all kinds of compounding agents are fully dispersed in the rubber compound, and to ensure that the required physical and mechanical properties and calendering, Requirements for process operations such as extrusion.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits