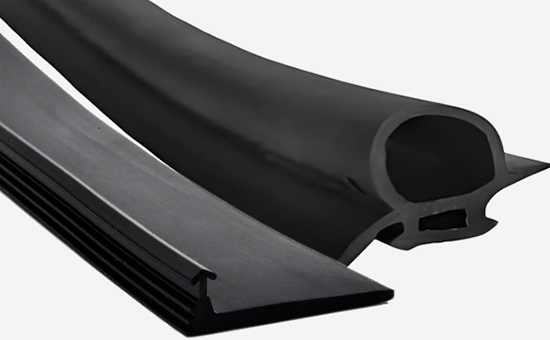

Rubber extrusion is a process in which the rubber material is continuously shaped through a certain shape of mouth shape (hollow products are mouth-shaped cored type) under the extrusion of the extruder screw. Rubber seals, rubber tubes, waterproof membranes, etc. produced with EPDM as the main raw material are all formed by extrusion process. The production cost of EPDM extrusion products is determined by the cost of materials and output, and if you want to reduce the cost of EPDM extrusion materials, you can start from the following three aspects.

1. Appropriately increase the amount of filler and rubber oil

EPDM has a low density and can be filled with fillers and rubber oil in large quantities; Appropriately increasing the amount of filler in the formulation of EPDM extruded rubber products is an effective way to reduce costs.

(1) Filler addition skills

Calcium carbonate, terracotta and other inorganic fillers have low prices, and are the most commonly used fillers in the production of EPDM extrusion rubber products. It should be noted that the inorganic filler has a large particle size, strong surface hydrophilicity, poor compatibility with rubber, and the reinforcement performance is far inferior to carbon black. If necessary, the surface modification of the filler can be carried out, such as calcium carbonate treated with titanate coupling agent to replace part of the silica, which can reduce the amount of high-priced silica and improve the tear resistance of the compound.

(2) Rubber oil addition skills

When EPDM produces extrusion products, paraffin oil and naphthenic oil are used to reduce the viscosity of the compound and improve the extrusion fluidity. Increasing the amount of rubber oil appropriately can reduce the viscosity of the rubber material and reduce the energy consumption of extrusion. The design of EPDM extrusion rubber products softening and plasticizing system should pay attention to the compatibility among rubber oil and vulcanization system; It is recommended to use paraffin oil for EPDM rubber extrusion using peroxide vulcanization.

2. Use EPDM recycled rubber to replace a certain proportion of EPDM raw materials

EPDM recycled rubber is a recycled rubber resource processed by classification, crushing, desulfurization, filtration and other processes from EPDM head rubber, unvulcanized EPDM head rubber, unvulcanized EPDM rubber or waste EPDM rubber products such as sealing strips, sealing rings, etc., retaining the basic performance characteristics of EPDM raw rubber, the price is only 20%-50% of the original rubber, in EPDM extrusion can replace part of EPDM raw rubber, effectively reduce the cost of raw materials; Some EPDM extrusions can even be completely made of EPDM recycled rubber.

Compared with EPDM rubber, EPDM recycled rubber has better fluidity, which can reduce extruder torque and improve production efficiency.

3. Increase the extrusion rate of EPDM compound

(1) The effect of EPDM raw materials and compounding properties on the extrusion rate of compounds

The extrusion rate of EPDM extrusion compound is related to the crystallinity of the rubber, and the extrusion rate of EPDM with high crystallinity is high. The extrusion rate of EPDM compound filled with low specific surface area carbon black is high. Organosilane can be used together with silica, not N330, to improve the extrusion rate of the compound. Adding special talcum powder to the compound can effectively increase the extrusion rate of the compound and maintain high-quality extrusion.

(2) Improve the extrusion process conditions of EPDM extrusion compounds

Kneading and preheating EPDM compound and adding it to the cold feeder can improve the extrusion output and quality. Adjust the screw design according to the viscosity of the compound, and when the viscosity of the EPDM compound is high, it is recommended to adopt a low-shear screw E5LYY322 design to reduce the risk of glue breakage. Properly increasing the screw temperature and reducing the barrel temperature can achieve higher output and less increase in compound temperature. Minimize the temperature difference among the extruder and the feed to achieve high output and high quality of extrusion.

When using EPDM as the main raw material to produce extruded rubber products, taking appropriate measures to reduce the cost of extruded rubber raw materials and production energy consumption is crucial to improve the market competitiveness of products, especially when the price of EPDM rubber rises and material shortages, it is imperative to rationally use low-priced rubber raw materials.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits