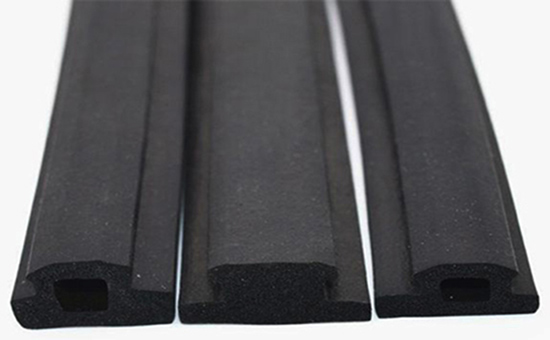

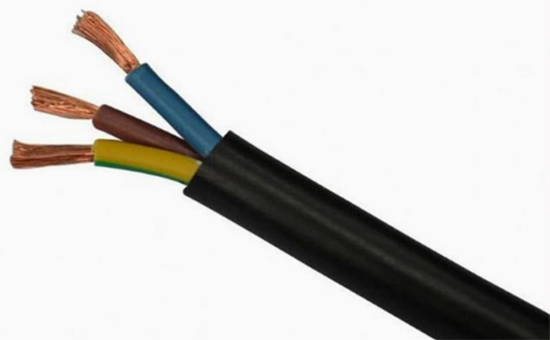

EPDM reclaimed rubber has the characteristics of high and low temperature resistance, aging resistance, high insulation, etc. It can be used alone or in combination with EPDM raw rubber to produce various kinds of extruded rubber products, such as rubber sealing strips, extruded rubber tubes, wire and cable skins, and many of them require smooth and bright surfaces; How to ensure the smooth surface of EPDM reclaimed rubber during extrusion? The manufacturers of EPDM recycled rubber products can consider the selection of raw materials and excipients and the extrusion process.

1. Pay attention to impurities in raw and auxiliary materials of ethylene propylene diene monomer recycled rubber extrusion

When using EPDM reclaimed rubber as the main raw material to produce extruded rubber products such as rubber tubes and strips, the moisture content and impurities in rubber raw materials and rubber accessories must be strictly controlled; It is recommended to use 60-80 mesh ethylene propylene diene monomer recycled rubber with high fineness and no impurities to ensure smooth and bright extrudate. Powdered rubber accessories, such as sulfur and calcium carbonate, must be stored separately to keep the storage environment clean and tidy. If necessary, the powdered compounding agent can be screened or dried in advance; Avoid unevenness or bubble on the surface of extruded rubber due to excessive impurities or moisture.

2. Pay attention to the extrusion process conditions of EPDM recycled rubber

During the extrusion process of ethylene propylene diene monomer (EPDM) reclaimed rubber, there are many reasons for the unsmooth surface of the extrudate, mainly focusing on the following four points:

(1) The extrusion temperature is low, and the surface of extruded semi-finished products is uneven or has "pimple" shaped pockmarks. Therefore, when the EPDM reclaimed rubber is extruded, the extrusion process parameters must be strictly controlled, and the temperature of each section of the extruder must be set according to the regulations; In the production process, increase the frequency of temperature measurement at the extruder head to ensure that the extrusion temperature does not fluctuate.

(2) The traction speed of linkage line is slower than the extrusion speed, resulting in wavy bending or twisting of the extruded semi-finished EPDM reclaimed rubber. Adjust the traction speed of linkage line to ensure that the extrusion speed of semi-finished products matches the traction speed of linkage line.

(3) The EPDM recycled rubber was preheated unevenly or the returned rubber was mixed unevenly. Improve the quality awareness of operators, standardize the operation methods, and set and operate the process parameters in strict accordance with the operation procedures; Ensure uniform mixing of rubber materials, strictly control the mixing proportion of returned rubber, and adopt double tables or more

The table supplies glue to ensure the uniformity of glue.

(4) The surface finish of the die plate of the extruder is not enough. Grind and level the surface of the die plate.

There are other points needing attention to improve the surface smoothness of EPDM recycled rubber extrusion compound. Xiao Bian has the opportunity to continue to discuss relevant issues with you.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits