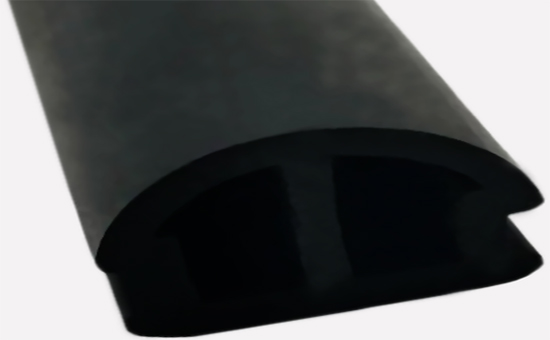

The rubber mixture is the rubber material obtained by mixing raw rubber or plastic rubber according to the formula and the mixing agent through the rubber mixing machine, which directly affects the quality of rubber products. When producing rubber products with ethylene propylene diene monomer recycled rubber as the main raw material, the ethylene propylene diene monomer recycled rubber needs to be fully cooled, filtered and parked as the original rubber after mixing to provide a better basis for the subsequent production process operation. In actual production, the following problems should be paid attention to when cooling, filtering and parking ethylene propylene diene monomer (EPDM) reclaimed rubber.

1. Precautions for cooling EPDM reclaimed rubber mixture

During the storage period, the temperature of EPDM reclaimed rubber mixture is high, which may cause scorching, adhesion and other problems, so it must be cooled. The cooling methods of EPDM reclaimed rubber are different due to different mixing methods. For example, the ethylene propylene diene monomer (EPDM) reclaimed rubber 2ELYY128 mixed with the open mill can directly soak the film cut from the open mill into the water tank with isolating agent, and then take it out to dry; After mixing ethylene propylene diene monomer recycled rubber in the internal mixer, the hanging film cooling device can be used for forced cooling.

2. Precautions for EPDM reclaimed rubber compound filtration

In order to prevent the rubber from burning, it is necessary to filter the master batch rubber without vulcanizing agent, accelerator and foaming agent in the production of ethylene propylene diene monomer recycled rubber products. Ordinary EPDM recycled rubber products can be combined with one layer of 20 mesh skeleton screen and two layers of 80 mesh filter screen; During the rubber filtering process, pay attention to the regular replacement of the filter screen to prevent impurities from breaking through the filter screen after the filter screen is blocked, which can not filter impurities.

3. Precautions for EPDM reclaimed rubber mixture parking

It is recommended to park the EPDM reclaimed rubber mixture for more than 24 hours after mixing and filtering to fully eliminate rubber fatigue, relax the mechanical stress during mixing and reduce rubber shrinkage. The temperature, humidity and storage time of the rubber compound containing curing agent must be controlled during storage in the warehouse to avoid scorching or moisture absorption. It is not suitable to store it for a long time; The remaining returned rubber materials after use shall be kept separately and shall not be mixed with the original film. When the EPDM reclaimed rubber mixture is parked, the environment shall be ventilated, free of water and direct sunlight, the indoor temperature shall be controlled among 15-30 ℃, and the humidity shall not be less than 70%; Maintain the "first in, first out" principle.

When producing rubber products with EPDM reclaimed rubber as the main raw material, each production process must be strictly controlled. Later, Xiaobian will continue to share with you the key points of EPDM reclaimed rubber vulcanization, molding process and precautions.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits