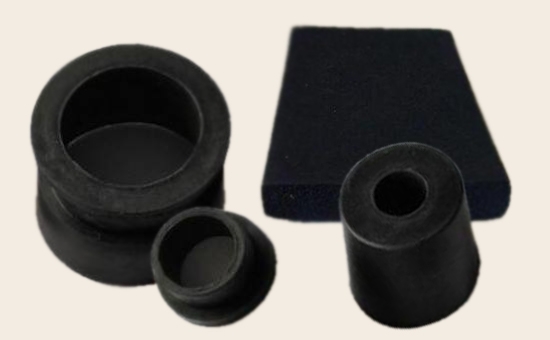

EPDM rubber has excellent ozone resistance, heat resistance, weather resistance, etc., and is widely used in auto parts, wire and cable sheaths, heat-resistant hoses, tapes, seals, etc. In actual production, EPDM rubber has a low density and can be filled with rubber oil and fillers in large quantities. Appropriate use of low-cost raw and auxiliary materials can effectively reduce the cost of raw materials while ensuring product quality. The editor today shares two low-cost EPDM rubber product formulas with you.

1. Low cost EPDM black molding compound formula

100 parts of EPDM rubber, 5 parts of active zinc oxide, 2 parts of stearic acid, 150 parts of carbon black N550, 150 parts of light calcium, PEG- 2.5 parts, 100# engine oil 120 parts, sulfur 2 parts, accelerator TT 0.7 , 1.5 parts of accelerator BZ, 1.5 parts of accelerator DM, 1.3 parts of accelerator CZ; total: 536.5.

The hardness is 72 degrees, the tensile strength is 7MPa, the elongation at break is 330%, the tear strength is 27kN/m, and the permanent deformation at break is 20%.

2. Reference formula of high-filled high-quality microwave sulfur rubber compound

100 parts of EPDM rubber, 5 parts of activated zinc oxide, 1 part of stearic acid, 135 parts of carbon black N550, 70 parts of light calcium (superfine), 2 parts of PEG, 2 parts of rubber processing aid UL-250, 300 # Paraffin oil 95 parts, pretreated calcium oxide 13 parts, sulfur 1.4 parts, accelerator TT, 0.7 parts, accelerator BZ 2.3 parts, accelerator M 2 parts, accelerator DTDM 0.8 parts; total: 430.2 parts. Vulcanization parameters: 160℃×10min.

The hardness is 70 degrees, the tensile strength is 9MPa, the elongation at break is 330%, and the permanent deformation at break is 12%.

3. Skills to reduce the cost of EPDM rubber products

(1) Raw rubber: Choose high molecular weight, high ethylene content EPDM rubber to ensure higher filling capacity, better strength and molding stiffness of the rubber, and ensure good processing performance of the large amount of filled rubber. Vulcanized rubber 2LLYY1216 has higher tensile strength, tear strength and aging resistance. Part of the styrene butadiene rubber or butadiene rubber is used in the EPDM rubber to reduce the cost of raw rubber while ensuring the aging resistance of the product. Use appropriate amount of EPDM reclaimed rubber to reduce the amount of expensive raw rubber, improve the process, and reduce costs.

(2) Compounding agent: Under the premise of meeting the needs of EPDM rubber products, use low-priced inorganic fillers such as calcium carbonate, clay, talc, or fill an appropriate amount of vulcanized rubber powder to significantly reduce the cost of raw rubber. Use paraffin oil, increase the amount appropriately, or use lower cost mechanical oil or aromatic oil to further reduce the cost of EPDM rubber products. Choose common sulfur vulcanization system to vulcanize, the cost of compounding agent is low, the physical and mechanical properties of EPDM vulcanizate are good, and the production efficiency is high.

Reducing the production cost of EPDM rubber products can be considered in terms of raw material prices and production energy consumption. It should be noted that: You must not reduce costs at the expense of the quality of rubber products. All the above methods are to ensure product quality Under the premise of.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits