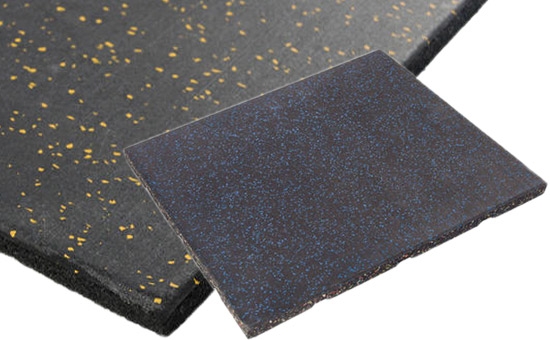

Rubber cushioning pads can be widely used in indoor and outdoor fitness equipment, playing multiple functions of shock absorption, noise reduction, and cushioning. Among them, the shock cushions of outdoor fitness equipment are mostly made of EPDM reclaimed rubber as the main raw material. Low production cost, good performance and long life. In actual production, when using EPDM reclaimed rubber to reduce the production cost of outdoor fitness cushions, rubber mat manufacturers need to carefully choose EPDM reclaimed rubber, and use reclaimed rubber reasonably under the premise of ensuring quality.

1. Selection of EPDM reclaimed rubber

Cushion pads for outdoor fitness equipment generally require a smooth surface, good elasticity, no cracks, delamination, bubbles, etc., and are not prone to discoloration and migration. The product has excellent weather resistance and ozone resistance, and no harmful substances can be produced during use. When using EPDM reclaimed rubber for outdoor rubber cushion 2LLYY112, choose environmentally friendly EPDM reclaimed rubber with high rubber content and high fineness, odorless EPDM reclaimed rubber, and reduce the cushion rubber under the premise of ensuring quality. Cost of production.

2. Outdoor rubber buffer compound formula

When using EPDM reclaimed rubber to reduce the raw material cost of cushion rubber pads for fitness equipment, an appropriate amount of butadiene rubber can be used in the cushion formula with EPDM reclaimed rubber as the main raw material to further improve the cold resistance and resistance of the cushion Abrasiveness and elasticity. Outdoor rubber cushions can choose the traditional sulfur vulcanization system, or use sulfur and peroxide together to further improve the heat resistance and compression set resistance of the rubber cushion; use carbon black to reinforce, calcium carbonate and appropriate tire rubber powder filling; Choose softening oil or plasticizer that is not easy to migrate.

In actual production, an appropriate amount of flame retardant can be added to the formula of EPDM reclaimed rubber cushion to improve the safety of use; if it is used to produce foam foam cushion rubber, the rubber product manufacturer also needs to design the foaming system reasonably. Foaming agent H is more common.

3. EPDM cushion processing

When using EPDM reclaimed rubber to prepare low-cost cushioning cushions, the rubber cushion manufacturer can test the basic indicators of the reclaimed rubber, determine the processing characteristics, and then determine the processing according to the performance of the compounding agent used in the outdoor cushioning cushion and the actual performance requirements of the product. Conditions, especially mixing temperature, vulcanization temperature, etc. When EPDM reclaimed rubber is used together with butadiene rubber, the butadiene rubber is fully masticated and then blended with EPDM reclaimed rubber, and the final production conditions are determined by combining the process performance characteristics of the two rubber raw materials.

The reasonable use of EPDM reclaimed rubber for outdoor cushioning pads can significantly reduce the cost of raw materials. Later editors will have the opportunity to discuss with you the formulation design of EPDM reclaimed rubber cushions.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits