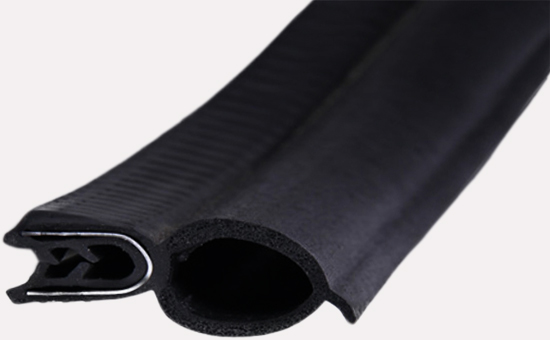

EPDM rubber has excellent ozone resistance, heat resistance, weather resistance and other aging resistance, and is an ideal raw material for the production of rubber seals, especially building door and window seals, automobile door and window seals, etc. that have been working outdoors for a long time. EPDM recycled rubber retains the basic performance characteristics of EPDM rubber, and the price is much lower than that of EPDM raw rubber, which can replace high-priced raw rubber to produce rubber seals and effectively reduce raw material costs. The application of EPDM recycled rubber in rubber sealing strips is mainly as follows.

1. Completely use EPDM recycled rubber to produce rubber seals

EPDM recycled rubber is processed from EPDM head adhesive, unvulcanized EPDM or waste EPDM products such as (door E5LYY78 and window seals, washing machine seals, etc.) as raw materials, and the processing process breaks the cross-linking network of waste EPDM, so that it changes from an elastic state to a certain plastic and viscous rubber that can be reprocessed vulcanized, retains the characteristics of EPDM rubber resistance to high and low temperature, ozone resistance, aging resistance, etc., and can directly replace EPDM rubber to produce various rubber sealing strips. Effectively reduce raw material costs.

2. EPDM recycled rubber and EPDM rubber are used together to produce rubber sealing strips

EPDM recycled rubber has good compatibility with EPDM rubber, and can produce high-performance rubber sealing strips in any proportion, reducing the cost of rubber on the premise of ensuring the performance of the sealing strip. Compared with pure EPDM rubber, the expansion and contraction of unvulcanized rubber with EPDM recycled rubber are much smaller during processing than that of unvulcanized rubber with only new rubber, and the shape and size of the finished EPDM sealing strip are more accurate.

3. EPDM recycled rubber and plastic are used together to produce rubber sealing strips

EPDM recycled rubber can be used with low-density polyethylene, polyvinyl chloride, etc. to produce rubber seals, and an appropriate amount of EPDM can also be added to the formula; The combination of rubber and plastic can solve the performance shortcomings of a single material, and at the same time meet the comprehensive needs of sealing strips for weather resistance, flexibility, cost and processability.

Low-density polyethylene can improve the processing fluidity of EPDM compounds such as extrusion and calendering, reduce the friction among the compound and the surface of the equipment, increase the extrusion speed and reduce the risk of scorching, and further improve the dimensional stability and stiffness of the finished sealing strip. EPDM recycled adhesive is used together with an appropriate amount of polyvinyl chloride to improve the processing process performance of the rubber material, and to a certain extent to improve the tensile strength and tearing elongation of vulcanized glue.

When using EPDM recycled rubber to produce rubber seals, reasonably determine the mixing ratio of recycled rubber and reasonably design the EPDM recycled rubber sealing strip formula, which can reduce more raw material costs while ensuring the quality of finished products.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits