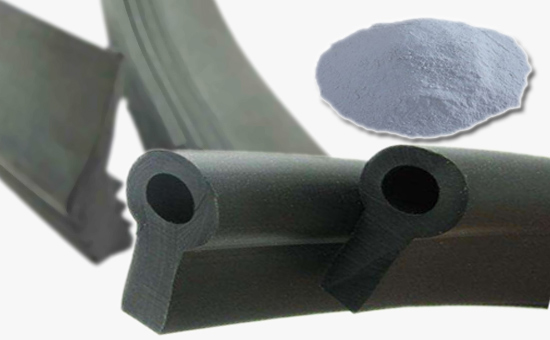

Nitrile seals are made from nitrile rubber (currently there are many rubber product manufacturers that use nitrile reclaimed rubber) as raw materials, have excellent oil resistance and good heat resistance, chemical stability, can be used in various Seals in oil media maintain good sealing performance. Silica is a commonly used reinforcing agent when producing sealing tapes using nitrile regenerated rubber/rubber, especially in various light-colored and colored nitrile seals; but white carbon can be said in nitrile seals. Is a double-sided doll, can improve the performance of nitrile seal but also lead to certain indicators, so the white carbon in nitrile seal can not be added.

1、Why add white carbon black in nitrile seal

White carbon black is one of the commonly used reinforcing agents in the rubber product industry. It has unique porosity, large specific surface area, small particles, complex structure of aggregates, tight molecular arrangement, and strong surface adsorption, which can improve the reinforcement of rubber products. Abrasion resistance, anti-aging, delay the appearance of the surface of rubber products fade. After the white carbon black is added to the nitrile seal, the gel formed by the reaction of the white carbon black and the nitrile rubber/reclaimed rubber will increase the deformation resistance of the vulcanized rubber against external forces, thereby significantly increasing the hardness and pulling of the nitrile vulcanizate. Elongation strength, tear strength, etc. improve the sealing performance of nitrile sealant strips; improve the oil resistance and ozone resistance of nitrile seal strips and extend the service life of nitrile seal strips.

2. Why can not add white carbon black in nitrile seal

After white carbon black is added to the nitrile sealant rubber, white carbon reacts with the rubber molecules to form a gel, which hinders the movement of rubber macromolecules and molecular segments. Excessive amounts of silica will lead to the fluidity of the nitrile rubber compound. Deterioration and Mooney increase; With the increase in the amount of white carbon in the nitrile seal compound, the tensile strength of the rubber increases rapidly after a certain point; excessive use of white carbon, the resulting moisture It will affect the resilience of nitrile rubber/reclaimed rubber, so that the compression set of nitrile sealant rubber increases.

Under normal circumstances, when using nitrile rubber or nitrile reclaim adhesive to produce sealing strips, white carbon can be used as a reinforcing agent in the production of nitrile seals, based on 100 parts of raw rubber, and the amount of white carbon is best. Do not exceed 40 parts, so as not to cause part of the indicators of the nitrile seal to decrease, and the service life is shortened. The rubber product manufacturer needs to design the formula rationally; if you want to reduce the production cost while ensuring the quality of the nitrile seal, the seal manufacturer may wish Consider the production of nitrile rubber and nitrile regenerated rubber.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits