Knowledge

-

When it comes to reclaimed rubber shock absorbing materials, general rubber products manufacturers will choose tire reclaimed rubber, butyl reclaimed rubber or nitrile reclaimed rubber. Different applications a…

-

The proper use of tire rubber powder in natural rubber products can not only reduce the cost, but also improve the process performance and performance of natural rubber products. What problems should be paid at…

-

When using butyl reclaimed rubber to produce rubber products, rubber products manufacturers need to rationally adjust the formula of IR reclaimed rubber products to achieve the dual functions of ensuring qualit…

-

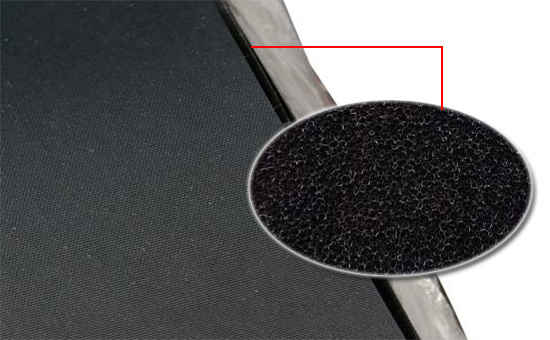

When using recycled rubber to produce rubber conveyor belts, different rubber layers need to be combined with different types of softeners. What are the commonly used softeners in the production of recycled rub…

-

In theory, the nitrile reclaimed rubber can be blended with pvc material and low density polyethylene to prepare oil-resistant rubber sheet, which can reduce the cost, improve the process performance of the rub…

-

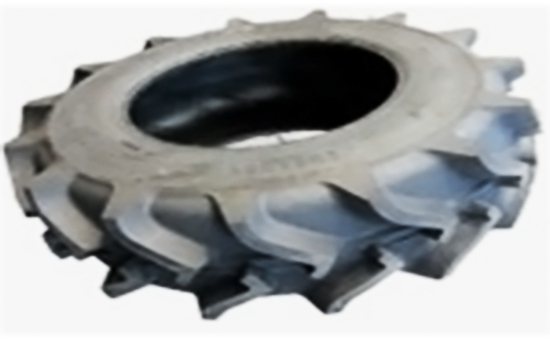

When using tire reclaimed rubber to produce agricultural tires, the rational design of agricultural tires and crown rubber can increase the amount of tire reclaimed rubber, and reduce the cost of raw materials …

-

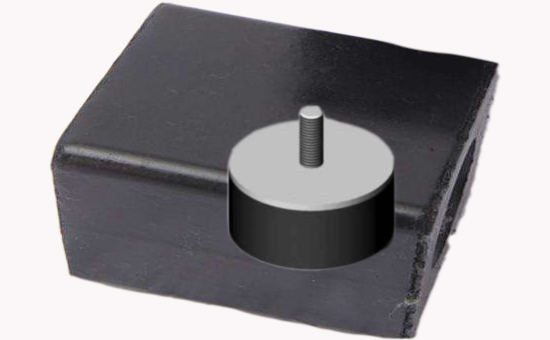

When using tire reclaimed rubber to reduce the production cost of rubber shock absorbers, rubber manufacturers need to adjust the natural rubber shock absorber formula containing tire reclaimed rubber according…

-

When using tire reclaimed rubber to reduce the production cost of rubber shock absorbers, rubber manufacturers must judge whether tire reclaimed rubber can be used in the product according to the use of the sho…

-

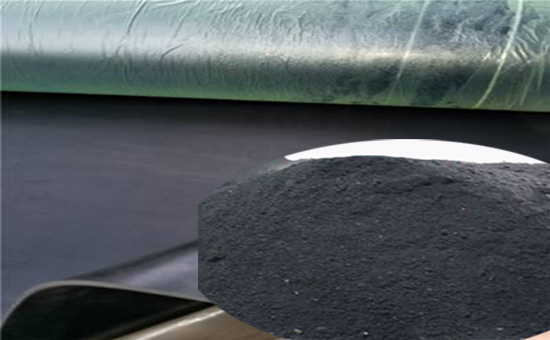

When using conductive rubber to produce conductive rubber products, acetylene black is indispensable; fast extrusion of carbon black can significantly improve the performance of recycled rubber. So, do these ca…

-

When using recycled rubber to produce rubber products, rubber manufacturers often use semi-reinforcing carbon black, spray carbon black, thermal black carbon, etc. What are the specific effects of these carbon …

-

The price of recycled rubber is much lower than the price of raw rubber. The price of many high-performance carbon blacks is higher than the price of recycled rubber. The main purpose of using carbon black in r…

-

Carbon black has an irreplaceable role in the production of recycled rubber products. Different types of carbon black are not used. Among them, channel black and general carbon black often appear in the formula…

-

The vulcanization rate of butyl rubber is slow. It is difficult to match the vulcanization rate and the foaming speed when preparing sponge foamed products. Therefore, certain measures are needed to improve the…

-

The use of tire reclaimed rubber in refurbishing tire liner rubber can reduce the cost of raw materials, but if it is used improperly, it will affect the performance and life of the tire. How should the tire re…

-

EPDM reclaimed rubber has excellent resistance to high and low temperature and aging resistance. It can be used in tire white tire side, automobile inner tube or tire production to improve the process performan…

-

When using latex reclaimed rubber to replace the natural rubber shock absorber for vehicles, it is necessary to determine the usage amount of the reclaimed rubber by combining the physical index and price of th…

-

When using natural rubber to produce rubber shock absorbers for vehicles, rubber shock absorber manufacturers can add appropriate amount of latex reclaimed rubber, tire reclaimed rubber or waste tire rubber pow…

-

At present, the tire rubber powder processed by the waste tire is simpler than the tire reclaimed rubber production process, and can be used as a filler in the acid-resistant rubber sheet formulation, which can…

-

The replacement of nitrile rubber with nitrile reclaimed rubber to produce rubber products can significantly reduce the cost of raw materials. Where can the nitrile reclaimed rubber be used? What problems shoul…

-

There are many types of carbon black, and their roles in recycled rubber products are not the same. When using recycled rubber to produce rubber products, rubber manufacturers can use two or more kinds of carbo…