Vulcanized rubber powder is made of waste rubber products by crushing at room temperature, freezing and chemical methods at room temperature. The fineness of common vulcanized rubber powder is about 30-100 mesh, which can be used as filler in rubber products. It can not only realize the recycling of waste rubber products, but also reduce the production cost and improve the rubber process performance. So in the production of rubber products, what are the functions of vulcanized rubber powder? Can I fill it up at will? What should be paid attention to when filling?

1. Function of vulcanized rubber powder in rubber products

Vulcanized rubber powder still retains the basic properties of rubber elastomer, so when a large number of rubber products are filled with vulcanized rubber powder, the technological properties and service properties of rubber compound can be improved appropriately, and the hardness and resilience of rubber compound will not be reduced as much as that of ordinary rubber filler. For example, the use of tire rubber powder 1jlyy1111 in tire tread rubber can increase the driving mileage and adaptability to road conditions; in a certain case, the rubber powder 1jlyy1111 can increase the driving mileage and adaptability to road conditions Some rubber products filled with EPDM powder can also improve the aging resistance of products.

2. Vulcanized rubber powder shall not be filled randomly in rubber products

Compared with other rubber fillers, vulcanized rubber powder retains the characteristics of rubber elastomer and has better bonding performance with rubber, but its reinforcement performance is poor. Therefore, the main purpose of filling rubber powder in hy rubber products is still to increase the volume of products and reduce the cost of raw materials. However, when rubber products are filled with vulcanized rubber powder in large quantities, the reaction point between rubber matrix and vulcanized rubber powder HD matrix is less, leading to the preparation of The mechanical strength and wear resistance of the product are reduced, especially for the coarse-grained vulcanized rubber powder. Therefore, the vulcanized rubber powder in rubber products cannot be filled in large quantities.

3. Filling skills of vulcanized rubber powder in rubber products

When filling vulcanized rubber powder in rubber products to reduce the production cost, the rubber products manufacturers need to first select the appropriate type of vulcanized rubber powder according to the performance requirements; then select the appropriate fineness products according to the production process and index requirements, generally rubber products with high mechanical strength and wear resistance requirements need to be filled with fine particle vulcanized rubber powder; extruded rubber products need to be filled with vulcanized rubber powder At least 80 mesh products should be selected; finally, the blending amount of vulcanized rubber powder should be reasonably determined according to the specific performance index of rubber products.

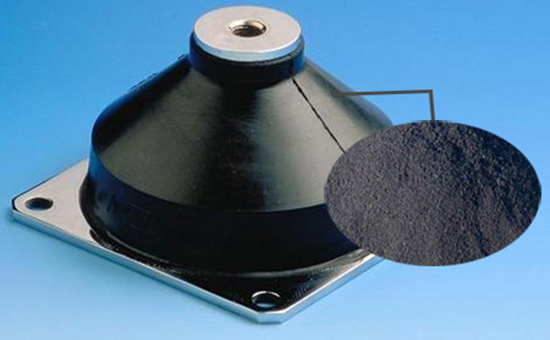

At present, vulcanized rubber powder is widely used as filler in the rubber products industry, such as waterproof roll, rubber sealing strip, damping block, etc. vulcanized rubber powder can be used. Some rubber products can be filled with vulcanized rubber powder in large quantity. At the same time of reducing cost, waste rubber products can be consumed to realize the recycling of resources. To further improve the production process of vulcanized rubber powder and expand the scope of application of vulcanized rubber powder can achieve multi win in resources, environment and economy.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits