Nitrile rubber is a special synthetic rubber with excellent oil resistance and good wear resistance obtained by emulsion polymerization of butadiene and acrylonitrile. SAN is AS resin, styrene-acrylonitrile copolymer, with high temperature resistance and resistance Chemical media properties; NBR and SAN are often used to make thermoplastic elastomers; many manufacturers now add a certain percentage of nitrile rubber powder to the NBR/SAN thermoplastic elastomer preparation process; why? What is the role of nitrile rubber powder in NBR/SAN blends?

1. Nitrile rubber powder replaces part of nitrile rubber to reduce costs

Nitrile rubber powder is a renewable resource processed from waste nitrile rubber products such as nitrile gloves and nitrile seals. It is excellent in heat resistance, cold resistance and wear resistance. The price is much lower than that of nitrile rubber. In theory, the filler is filled in NBR. The /SAN blend can replace part of the nitrile rubber to reduce the production cost of the NBR/SAN thermoplastic elastomer.

Feasibility analysis of NBR/SAN thermoplastic elastomer mixed with nitrile rubber powder

When the amount of AS resin is constant, the amount of nitrile rubber powder is increased, and the amount of nitrile rubber is appropriately reduced. The thermoplastic elastomer exhibits pseudoplastic behavior, which belongs to the heat rheological composite. The viscosity of the blend With the increase of the amount of nitrile rubber powder, it can be seen that the addition of nitrile rubber powder does not fundamentally affect the application performance of NBR/SAN thermoplastic elastomer; therefore, the NBR/SAN thermoplastic elastomer is blended with nitrile rubber powder to reduce the cost. It is completely feasible.

3. Nitrile rubber powder can improve the performance of NBR/SAN thermoplastic elastomer

The extrusion expansion ratio of the thermoplastic elastomer containing nitrile rubber powder and the NBR/SAN blend containing no nitrile rubber powder increases with the increase of shear rate; NBR/SAN thermoplastic containing nitrile rubber powder The elastomer outlet expansion rate is lower than the NBR/SAN blend outlet expansion rate; this is because the nitrile rubber powder contains reinforcing filler such as carbon black, which can reduce the extrusion expansion rate of the thermoplastic elastomer under the action of the reinforcing filler. , thereby improving the smoothness of the elastomer surface.

The nitrile rubber powder not only has excellent cold resistance, heat resistance, wear resistance and solvent resistance, but also prevents plasticizer migration, reduces permanent deformation of the copolymer, and improves the processing and processing of rubber and plastic products in the production of rubber and plastic products. Performance, physical properties and chemical resistance; therefore, nitrile rubber powder is widely used in the preparation of various thermoplastic elastomers, and it can reduce the cost of replacing the rubber raw materials while improving the overall performance of the thermoplastic elastomer.

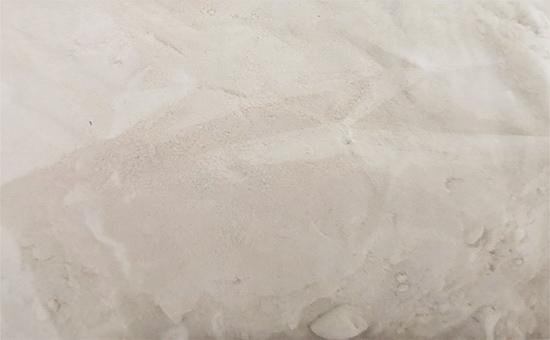

At present, the common nitrile rubber powder on the market mainly has black and white two colors and various fineness products. Rubber product manufacturers can select the appropriate variety of nitrile rubber powder according to actual needs.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits