EPDM rubber are widely used in the production of door and window seals, wire and cable, building waterproof materials, etc. due to their resistance to aging, water, corrosion and electrical insulation. In the production of many EPDM rubber products, rubber manufacturers will fill the appropriate amount of vulcanized rubber powder. Why? What are the main points to pay attention to?

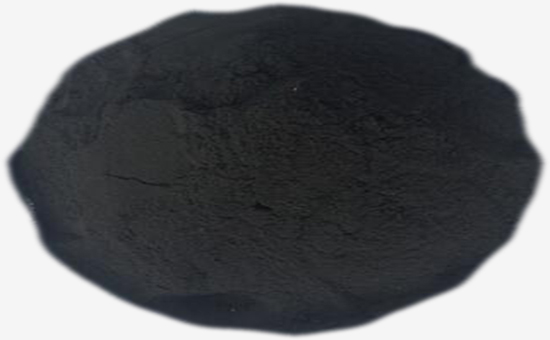

The rubber material which is pulverized or ground by the mechanical force shearing, freezing and the like is a vulcanized rubber powder. The common vulcanized rubber powder is tire rubber powder, EPDM rubber powder and nitrile. Rubber powder, in which tire rubber powder is processed from waste tires, and the raw material of EPDM rubber powder is mainly used for waste EPDM seals, both of which can be used in the production of EPDM rubber products. Improve performance, reduce costs, and alleviate the pressure on the environment caused by waste rubber products.

1. The tire rubber powder is made of waste tires, and the saturation of itself and EPDM rubber is very different, and the co-vulcanization performance of EPDM rubber is poor. Therefore, when filling tire rubber powder in EPDM rubber products, it must be Pay attention to the fineness, dosage and vulcanization system design of the tire rubber powder, and add appropriate modifiers to the formula to overcome the negative side of the tire rubber powder in the EPDM rubber products, and seek a cost and performance between the two. balance point. Regarding the use of tire rubber powder in EPDM rubber products, you can search for "adding skills of tire rubber powder in EPDM rubber products" in the station.

2. The application significance of EPDM vulcanizate powder in EPDM rubber products

The main raw material of EPDM vulcanized rubber powder is waste automobile sealing strip, which has good aging resistance, high and low temperature resistance, low density, low modulus and poor reinforcing performance. It is used as brightener in EPDM rubber compound. In practical applications, the physical and mechanical properties and wear resistance of EPDM rubber products will decrease with the increase of the amount of EPDM rubber powder for coarse particles. Therefore, it is best to use fine conditions and cost. Ion-active rubber powder (surface treatment by ultra-fine pulverization technology and chlorination, grafting, corona and other techniques, the cost is high); EPDM vulcanizate powder has little effect on the hardness and resilience of vulcanizate, so Rubber products manufacturers can use EPDM rubber powder as a non-reinforcing filler in the production of waterproof coiled materials and low-grade sealing products. It can solve the problem of disposal of used automobile sealing strips and reduce the production cost of EPDM rubber products.

The EPDM rubber product can also be used in combination with the rubber powder of the unsaturated diene rubber, and the problem of migration of the vulcanizing agent into the rubber powder can be noted.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits