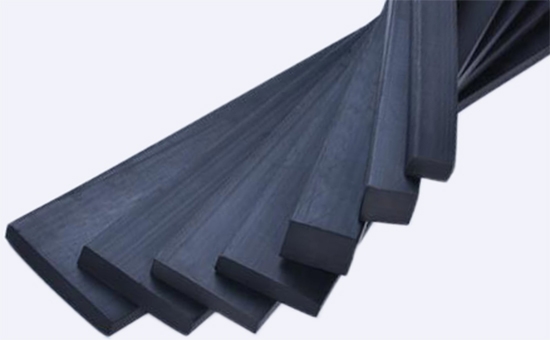

EPDM rubber powder made from waste EPDM rubber products and EPDM rubber scraps can be directly filled into various EPDM rubber products to reduce raw material costs. In actual production, the amount of EPDM rubber powder affects its filling effect in products, so how should EPDM product manufacturers choose EPDM rubber powder? How to ensure the best filling effect of EPDM powder in products?

1. Pay attention to the fineness of EPDM powder

When EPDM rubber powder is filled in EPDM rubber products to reduce raw material costs, rubber product manufacturers need to choose EPDM rubber powder with appropriate fineness according to the requirements of product type and surface smoothness. Under normal circumstances, ordinary molded rubber products can use about 40 mesh EPDM powder, products above 60 mesh are more favorable for the surface brightness of the product; use EPDM recycled rubber to produce extruded products such as extruded rubber strips, When extruding a hose, a 60-80 mesh or even finer EPDM rubber powder must be used to ensure the smooth extrusion of the extruded product, and the surface of the finished product is smooth, free of impurities, and free of unevenness.

Different fineness of EPDM rubber powder and EPDM rubber have different interface effects. Generally, the finer the product, the better the filling effect in EPDM rubber products.

2. The relationship between the amount of EPDM powder and the physical and mechanical properties of EPDM products

When EPDM is used in EPDM rubber products, various indicators of EPDM rubber products will change with the increase of the amount of rubber powder. Rubber product manufacturers can use this as a basis to appropriately increase or decrease the amount of rubber powder.

In general, 100 parts of EPDM rubber is filled with 50 to 200 parts of EPDM rubber powder, and the tensile strength and elongation at break of the rubber2LLYY0316 material will not change much. The amount of raw rubber and rubber powder will reach 1 : 1 ratio, the tensile strength and elongation at break can reach the optimal level.

When the filling amount of EPDM vulcanizate in EPDM rubber products continues to increase, the product's elongation stress will decrease with the increase of the amount of rubber powder, the tear resistance will decrease, and the hardness will remain basically unchanged. Yuan ethylene propylene rubber powder can also properly increase the elasticity and resilience of rubber products within a reasonable range of dosage.

When using EPDM rubber powder to reduce the production cost of EPDM rubber products, rubber product manufacturers must choose EPDM rubber products with appropriate fineness, reasonably control the addition ratio of rubber powder and EPDM rubber, and reduce costs. At the same time, to ensure the comprehensive indicators and service life of EPDM rubber products, the later editors will discuss with you a series of issues about EPDM vulcanized rubber powder formula design and processing process.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits