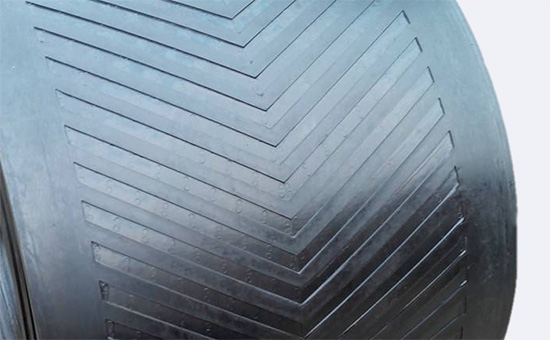

Waste rubber products can be processed into rubber powder with a certain degree of fineness, namely vulcanized rubber powder, by mechanical, freezing and crushing methods, and recycled into the production of rubber products to reduce raw material costs. In actual production, adding an appropriate amount of vulcanized rubber powder to the cover rubber of the rubber conveyor belt can achieve the dual purpose of reducing costs and improving performance. Does the conveyor belt cover rubber have any requirements for the performance indicators of vulcanized rubber powder? How much is appropriate? How to further optimize the comprehensive index of conveyor belt cover rubber?

1. The performance requirements of conveyor belt cover rubber for vulcanized rubber powder

When vulcanized rubber powder is mixed in the cover rubber of the conveyor belt, the higher the fineness of the vulcanized rubber powder, the better the mixing effect in the cover rubber. In actual production, conveyor belt covering rubber 2LLYY1020 generally uses about 80 mesh vulcanized rubber powder without impurities. If the cost permits, you can choose a higher mesh vulcanized rubber powder, which has better mixing effect and larger dosage.

2. The mixing effect of vulcanized rubber powder in conveyor belt cover rubber

(1) Process performance: When adding an appropriate amount of vulcanized rubber powder to the cover rubber of the ordinary conveyor belt, the powder will be eaten faster during the mixing process. After adding the rubber powder, it can be mixed for 3-4 minutes to release; the amount of rubber powder is more In the case of mixing, 1-2min can completely wrap the roll. The higher the fineness of the vulcanized rubber powder and the higher the surface finish of the film, the easier it is to disperse in the conveyor belt cover rubber. During vulcanization, the use of vulcanized rubber powder will speed up the vulcanization of the conveyor belt cover rubber to a certain extent.

(2) Finished product performance: When the conveyor belt cover rubber uses vulcanized rubber powder to reduce the raw material cost, the addition of vulcanized rubber powder will cause the tensile strength of the rubber to decrease, the tearing strength to increase, the wear resistance is improved, and the heat aging resistance is basically stay the same.

3. Usage and dosage of vulcanized rubber powder in conveyor belt cover rubber

When using vulcanized rubber powder to reduce the cost of conveyor belt covering rubber products, the tearing performance of sulfur vulcanized rubber is better, and the amount of vulcanized rubber powder is generally controlled between 10-20 parts. In order to further improve the blending effect of vulcanized rubber powder, rubber conveyor belt manufacturers can refine the rubber powder on an open mill with a small roller pitch to further destroy the original cross-linked structure in the rubber powder, increase the surface area of the rubber powder particles, and increase the vulcanized rubber The combination of powder and basic rubber material will then improve the comprehensive index of conveyor belt cover rubber.

In actual production, the use of refined vulcanized rubber powder for conveyor belt cover rubber can appropriately increase the amount of rubber powder, with low product cost and better overall performance; or choose a traditional sulfur vulcanization system to further improve the conveyor belt coverage containing vulcanized rubber powder Gel physical index.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits