Butyl rubber has excellent air tightness, water tightness, heat resistance, chemical stability, etc., which can be used to produce various high air tightness rubber products, heat-resistant products and anti-corrosion rubber products. However, in terms of performance and cost of some rubber products, it is impossible to achieve the goal by using butyl rubber alone. At this time, butyl rubber and other kinds of polymers need to be used together To improve the comprehensive properties of butyl rubber products.

1. Blending of butyl rubber and chlorosulfonated polyethylene

Chlorosulfonated polyethylene (CSPE) is a white elastomer produced by chlorination and chlorosulfonation of polyethylene. It has excellent ozone resistance, aging resistance, chemical stability, high and low temperature resistance, wear resistance and electrical insulation, etc. the weather resistance of butyl rubber itself is poor. Blending with CSPE can further improve the weather resistance of butyl rubber products, and to a certain extent increase Hardness of butyl vulcanizate, reducing adhesion of vulcanizate surface.

2. Blending of butyl rubber and chlorinated butyl rubber

The chlorinated butyl rubber prepared by introducing chlorine into butyl rubber solution retains the basic properties of DJ butyl rubber, and its vulcanization performance, aging resistance, weather resistance and adhesion with metal materials are better than that of butyl rubber. Therefore, butyl rubber and chlorinated butyl rubber 1jlyy115 can be used together to improve the curing speed of rubber compound, improve the adhesion between rubber product surface and other materials, further improve the flexing resistance and flexibility of butyl rubber products, and extend the service life of products.

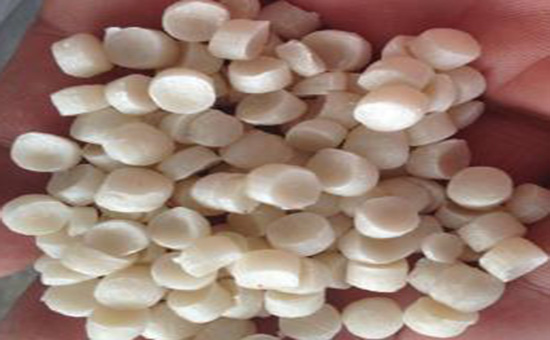

3. Blending of butyl rubber and polyisobutylene

Polyisobutylene is a kind of polymer which is made from isobutylene by direct dissociation polymerization. It is resistant to air permeability, ozone, chemical corrosion and acid medium. Therefore, the combination of hy butyl rubber and polyisobutylene (15-25 phr) can improve the ozone resistance and acid resistance of butyl rubber products. The addition of polyisobutylene with less than 5 phr in butyl rubber can improve the mechanical properties of butyl rubber products Strength.

The blending of butyl rubber and polymer can improve the comprehensive properties of butyl rubber products. But the blending of butyl rubber and polymer can not only improve the properties of products, but also reduce the cost of raw materials. In the actual production, butyl rubber can also be blended with low-density polyisobutylene, EPDM and butyl reclaimed rubber in proper proportion. Tomorrow, Xiaobian will continue to share with you the role of blending butyl rubber with other polymers.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits