Knowledge

-

The use of butyl reclaimed rubber in sponge tires can significantly improve the ozone resistance, weather resistance and heat resistance of natural rubber sponge tires, and reduce the production cost of sponge …

-

The use of reclaimed rubber in tire sidewall rubber can reduce the cost and improve the processing technology. Reasonable selection of the side rubber compounding agent containing reclaimed rubber can also incr…

-

The use of an appropriate amount of activated rubber powder in natural rubber products can improve the physical properties of the rubber compound and prolong the service life of the rubber product. What are the…

-

The use of latex reclaimed rubber to produce sponge styrofoam strips can reduce the cost of raw materials. However, if improper selection of compounds or unreasonable formula design will affect the extrusion pr…

-

The use of rubber powder obtained by mechanical pulverization or freeze-pulverization of used rubber products in the processing of products will cause problems in the physical and mechanical properties of rubbe…

-

Reasonable raw material selection and formula design are the basis for ensuring the quality of high-hardness nitrile reclaimed rubber products, but even the best "ideas" need to be implemented, and the sample c…

-

The nitrile reclaimed rubber processed from different raw materials can be used to produce nitrile rubber products of various hardnesses. Among them, oil-resistant hoses, rubber rollers, glue sticks, rubber str…

-

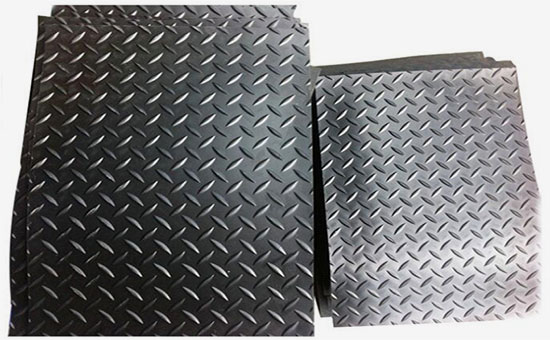

Rubber seals are a large category of rubber products, such as seals, gaskets, flanges, etc. Tread reclaimed rubber can reduce the cost of raw materials and improve the wear resistance and anti-aging of rubber s…

-

Butyl reclaimed rubber can not only be used to replace butyl rubber in the production of various high-air-tightness rubber products, shock absorbers, corrosion-resistant products, but also can replace butyl rub…

-

2018-10-17改善氧化锌混炼时分散性的办法Zinc oxide is a polyhedron in the production of rubber products. It can be used as an activator, accelerator, reinforcing agent, oxidant, etc. However, in actual production, zinc oxide is difficult to be unifor…

-

Butyl rubber plugs made from butyl rubber have replaced most of the natural rubber plugs. However, in actual production, improper selection of raw materials or improper production process will affect the yield …

-

Natural rubber has high mechanical strength, good elasticity and wide application. However, in the actual production process, if the rubber product manufacturer uses high temperature and rapid vulcanization to …

- EPDM reclaimed rubber is an ideal raw material to replace the raw material cost of the raw material of EPDM. Although the performance is basically consistent with the performance of EPDM, there are still some differences in actual use.

-

Reasonable formula design is the basis for ensuring uniform mixing of EPDM reclaimed rubber. However, if the operation is improper during the actual mixing process, the problem of poor dispersion of EPDM reclai…

-

EPDM rubber containing EPDM reclaimed rubber is generally mixed with an internal mixer, but there may be problems of poor dispersion during the actual mixing process. Why? What measures should be taken to solve…

-

Adding the right amount of recycled rubber powder to the POE sole can improve the wear resistance, wet skid resistance and aging resistance of the sole. Why? What proportion of recycled rubber powder can be add…

-

Carbon black is the most commonly used reinforcing filler in rubber products. Different types of carbon black have different molecular structure characteristics and different roles in rubber products. How do di…

-

The use of tire reclaimed rubber in automotive tire tread rubber can reduce the cost of raw materials, and also ensure its good resilience, wear resistance, tear resistance and flex resistance. How to design th…

-

Calcium silicate composed of silica, calcium oxide, water and iron oxide has better reinforcing effect on latex reclaimed rubber than natural rubber, and it is used together with carbon black to improve the vul…

-

As the most commonly used reinforcing agent in the production of reclaimed rubber products, carbon black can not only significantly improve the tensile strength and elongation at break of recycled rubber produc…