Butyl Rubber Encyclopedia

-

When using butyl rubber/butyl reclaimed rubber to produce rubber products, when choosing paraffin oil for softening, the amount of paraffin oil directly affects the physical and mechanical properties of the vul…

-

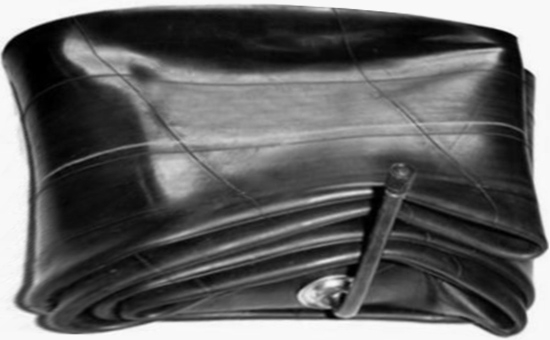

Chlorinated butyl reclaimed rubber can replace a certain proportion of chlorinated butyl rubber to produce butyl inner tubes and vulcanized bladders. Reasonable use of chlorinated butyl reclaimed rubber and pro…

-

The rational use of chlorinated butyl reclaimed rubber in tubeless tire innerliner and tire sidewall rubber can not only improve the performance of the finished product, but also effectively reduce the cost of …

-

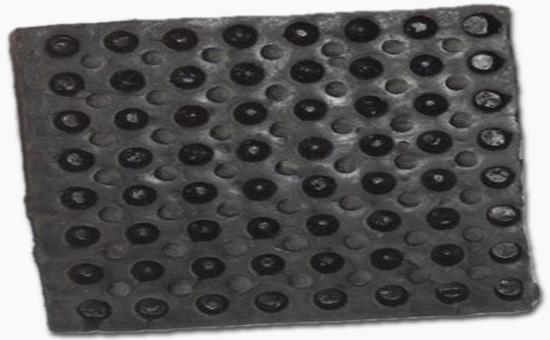

Using butyl reclaimed rubber as the main raw material to prepare sound insulation boards has low cost and good performance, and can be used in various fields. In actual production, choosing the appropriate comp…

-

Combining natural rubber and butyl reclaimed rubber in an appropriate ratio can not only reduce the cost of raw materials, but also meet the needs of more rubber products. Appropriate adjustment of the natural …

-

The use of butyl reclaimed rubber can improve the process performance of EPDM swelling rubber in contact with oil and reduce the cost of raw materials. So what will happen to EPDM oil-expanded rubber after addi…

-

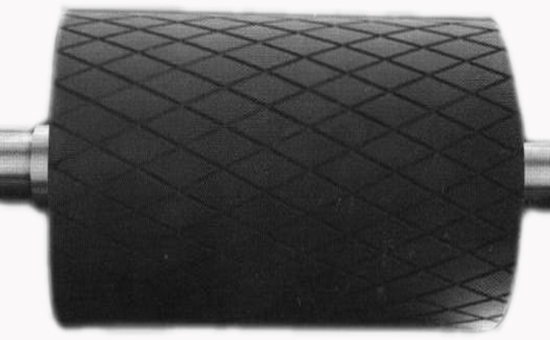

When using butyl reclaimed rubber to reduce the production cost of rubber rollers, rubber products manufacturers can choose to use butyl reclaimed rubber together with butyl virgin rubber, or use butyl reclaime…

-

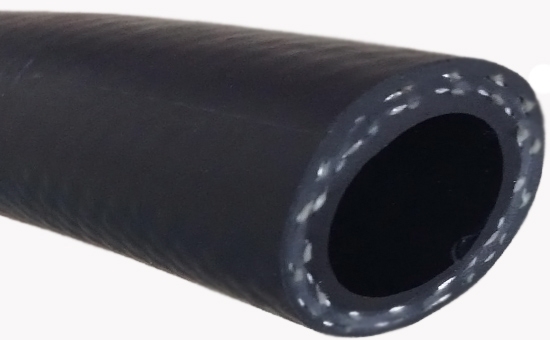

When using butyl reclaimed rubber to reduce the raw material cost of acid and alkali resistant hoses, rubber product manufacturers need to reasonably control the amount of butyl reclaimed rubber, appropriately …

-

When using natural rubber to produce water tyres, proper use of butyl reclaimed rubber can not only improve the performance of water tyres, but also reduce the cost of raw materials, so how much butyl reclaimed…

-

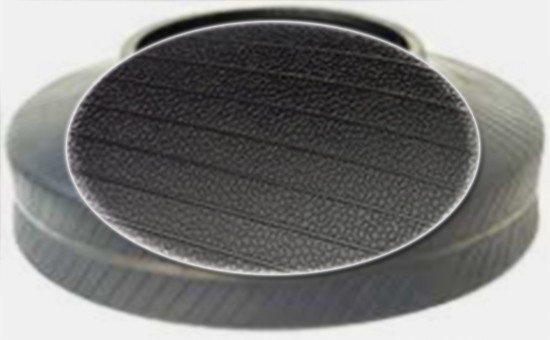

To reduce the raw material cost of butyl rubber air-conditioning damping block, rubber product manufacturers can use butyl reclaimed rubber or butyl rubber scraps in an appropriate amount, and reasonably adjust…

-

When the natural rubber is mixed with an appropriate amount of butyl reclaimed rubber, the amount of butyl reclaimed rubber is controlled within a reasonable range, which can not only improve the aging resistan…

-

2021-01-14Notes on butyl rubber mixingWhen using butyl rubber to produce products, rubber manufacturers need to ensure that mixing equipment is clean, mixing conditions are reasonably set, mixing process is strictly controlled, and butyl rubber is …

-

When using butyl rubber, natural rubber or EPDM rubber to produce products, rubber product manufacturers can choose the appropriate butyl reclaimed rubber according to actual needs to improve rubber processing …

-

When using chlorinated butyl rubber to produce automotive engine shock absorbers, rubber product manufacturers can use appropriate amounts of chlorinated butyl reclaimed rubber to effectively reduce raw materia…

-

When using butyl rubber or butyl reclaimed rubber to produce rubber products with strict requirements on air permeability, rubber products manufacturers need to select appropriate rubber raw materials and compo…

-

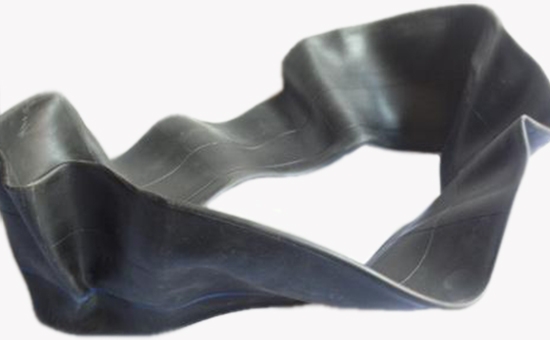

When butyl reclaimed rubber is used to prepare butyl innertubes, proper use of natural rubber can improve the overall performance of the innertube product, so how much natural rubber is appropriate? What should…

-

When using butyl reclaimed rubber instead of butyl virgin rubber to produce the inner tube formula, the rubber product manufacturer needs to adjust the amount of butyl reclaimed rubber according to actual needs…

-

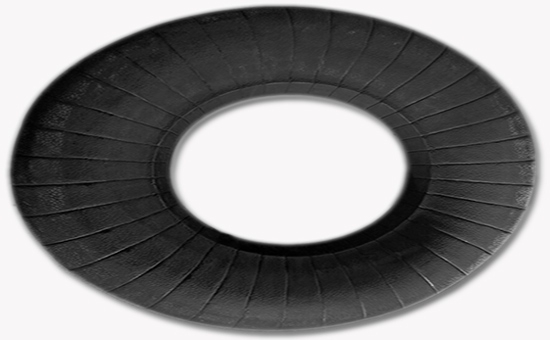

The plastic runway prepared by rational use of chlorinated butyl rubber has the basic properties of EPDM rubber particle runway, so what should be paid attention to in the preparation process? How to design the…

-

Many butyl reclaimed rubber products choose sulfur vulcanization in the production process, and the use of appropriate types of accelerators and activators can further optimize the vulcanization effect and bett…

-

When using butyl rubber/reclaimed rubber to produce heat-resistant hoses, the variety and amount of softeners not only affect the processing performance of the heat-resistant hose, but also affect the comprehen…