Chlorinated butyl reclaimed rubber is made of waste chlorinated butyl rubber products (such as pharmaceutical butyl stoppers) as raw materials through crushing, desulfurization, refining and other processes, with excellent air tightness and water tightness, heat resistance, chemical corrosion resistance, good aging resistance, can be used alone or with butyl rubber, chlorinated butyl rubber, other unsaturated rubber combined to produce rubber products, effectively reduce the cost of raw materials. When using chlorobutyl reclaimed rubber to produce rubber products, the design of the reinforcing filling system is very important, which directly affects the physical and mechanical properties and service life of the finished product.

1. Varieties and adding skills of commonly used reinforcing agents for chlorinated butyl reclaimed rubber

Reinforcing agent is a substance that can be used in large quantities in the production of rubber products and can significantly improve the tensile strength, tensile stress, tear strength, wear resistance and other indicators of rubber.

(1) Carbon black

Carbon black can significantly improve tensile strength and wear resistance by forming physical adsorption and chemical bonding with rubber molecular chains through high specific surface area, and different varieties of carbon black have different reinforcing effects on chlorobutyl reclaimed rubber. Generally, super wear-resistant carbon black, medium super wear-resistant carbon black, and high wear-resistant carbon black have good reinforcing effect, and fine-particle thermal cracking carbon black can improve the elongation at break and post-aging performance of chlorinated butyl reclaimed rubber vulcanized rubber.

(2) Silicone

Silica can give the rubber high tensile strength, elongation, elasticity, hardness, heat resistance and tear strength, its surface hydroxyl content is high, and the use of coupling agent can enhance the tear resistance and flexural resistance of the rubber compound. When using chlorobutyl reclaimed rubber to produce rubber products with high requirements for heat resistance and aging resistance, silica can be used to reinforce it in an appropriate amount. It should be noted that silica is highly alkaline, and the use of highly alkaline and hygroscopic fillers should be avoided in the formulation of chlorinated butyl reclaimed rubber products containing silica.

2. Varieties and adding skills of commonly used fillers for chlorobutyl reclaimed rubber

Filler is a substance that can be used in large quantities in the production of rubber products and can increase the volume of rubber, reduce costs, and improve the performance of rubber processing technology.

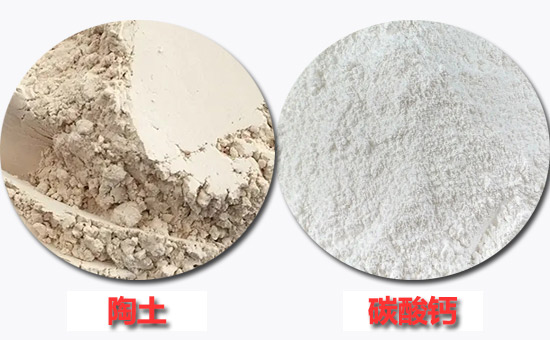

(1) Clay

Clay can be divided into hard clay and soft clay according to fineness, hard clay reinforcing performance is better than soft clay, has a certain reinforcing effect in the production of chlorobutyl reclaimed rubber products, the hardness, tensile stress and wear resistance of the rubber filled hard clay have been improved, but the tear resistance of vulcanized rubber is not good. The use of chlorobutyl reclaimed rubber to produce heat-resistant, acid-alkali resistant rubber products can be filled with clay. It should be noted that hard clay has a tendency to stick to rollers, especially the combination of chlorinated butyl reclaimed rubber and butyl original rubber, which requires an appropriate amount of magnesium oxide.

(2) Talc

The main components of talc are water and magnesium silicate, which can give the rubber a lower viscosity, improve the extrusion performance, reduce the mouth expansion and the strength of the unvulcanized rubber, and give the vulcanized rubber good air permeability, anti-swelling and good conductive insulation. Talc is easily dispersed in chlorobutyl reclaimed rubber, which will not affect the vulcanization performance of the rubber.

(3) Calcium carbonate

Calcium carbonate is the most commonly used filler in the production of rubber products, which can be divided into heavy calcium carbonate, light calcium carbonate and active calcium carbonate, which can effectively reduce the production cost of rubber products. Heavy calcium can improve the fluidity of rubber and reduce the surface defects of molded products. Light calcium can reduce the viscosity of rubber Mooney and improve the extrusion efficiency; Activated calcium carbonate has a certain reinforcing effect in rubber compounds. The reinforcing effect of calcium carbonate on chlorobutyl reclaimed rubber is low, and the heat resistance is not as good as that of clay and talcum powder, so it is mainly used as a filler.

(4) Inorganic fillers treated with silane coupling agents

The surface of the inorganic filler lacks the necessary activity, and the reinforcing effect in the rubber is generally poor, and the use of a small amount of silane coupling agent or as an additive can significantly improve the reinforcing effect of the inorganic fillerE4LYY912 on the chlorinated butyl reclaimed rubber.

The design of the reinforcing filling system of chlorobutyl reclaimed rubber products needs to comprehensively consider the types and dosages of reinforcing agents and fillers and the interaction among them, such as clay + talc powder + calcined clay, silica + silane coupling agent, etc.; Reasonable design of reinforcing filling system can significantly improve the mechanical properties, heat resistance, aging resistance, etc. of chlorinated butyl reclaimed rubber products, and reduce production costs.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits