Butyl Rubber Encyclopedia

-

The reclaimed butyl rubber can be used alone or together with butyl rubber to produce corrosion resistant products, effectively reducing the cost of raw materials. When butyl reclaimed rubber and butyl rubber/b…

-

When using butyl reclaimed rubber alone or butyl rubber/butyl reclaimed rubber in combination to produce rubber products, the demand for antioxidant is generally small, but for rubber products with special requ…

-

When producing rubber products with chlorinated butyl reclaimed rubber as the main raw material, the reinforcing agent directly affects the physical and mechanical properties of the finished rubber products. Xi…

-

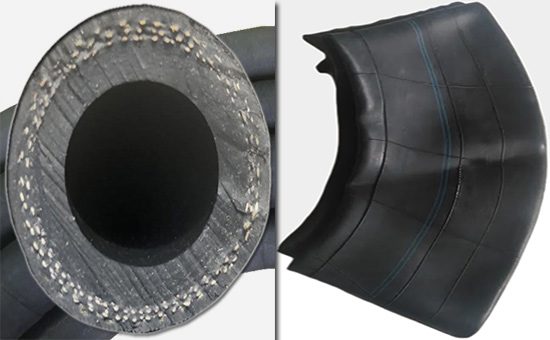

The butyl reclaimed rubber retains the basic performance characteristics of butyl rubber, with good air tightness, heat resistance and chemical corrosion resistance. It can not only be used to produce rubber se…

-

Butyl reclaimed rubber has excellent air tightness, good water tightness, heat resistance, chemical resistance, and shock absorption. It can be used alone or in combination with butyl rubber, ethylene propylene…

-

Vulcanization systems commonly used in the production of butyl reclaimed rubber products include sulfur accelerator system, resin curing system, etc. Carbon black is commonly used for reinforcement. For light c…

-

During the production of rubber products such as inner tube, heat-resistant rubber tube and sealant strip with butyl reclaimed rubber and butyl rubber/butyl reclaimed rubber as main raw materials, the extruding…

-

When butyl reclaimed rubber is used in automobile inner tube, selecting butyl reclaimed rubber with high butyl content and properly adjusting the formula can further improve the air tightness of butyl inner tub…

-

Chlorinated butyl reclaimed rubber is an ideal raw material to replace chlorinated butyl rubber to produce various rubber products and reduce costs. How is chlorinated butyl reclaimed rubber added to rubber pro…

-

The tread rubber of bias tire is generally processed from natural rubber, cis polybutadiene rubber and styrene butadiene rubber. Butyl reclaimed rubber has the characteristics of good air tightness and heat res…

-

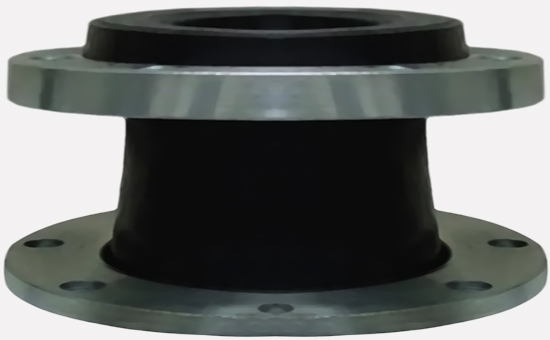

The reclaimed butyl rubber can directly replace the original butyl rubber or be used with EPDM to produce heat-resistant conveyor belts. The reasonable design of the formula can effectively reduce the cost on t…

-

Natural rubber has high mechanical strength and good elasticity, and is used in a large amount in the rubber product industry. However, natural rubber itself is resistant to heat-oxidative aging, ozone aging, a…

-

The main function of the airtight layer is to prevent the leakage of compressed gas, and it is generally processed from chlorobutyl rubber with excellent air tightness as the main raw material. As a new type of…

-

Improving the heat resistance of butyl reclaimed rubber can further prolong the service life of heat-resistant rubber products. So what aspects should rubber product manufacturers start from to improve the heat…

-

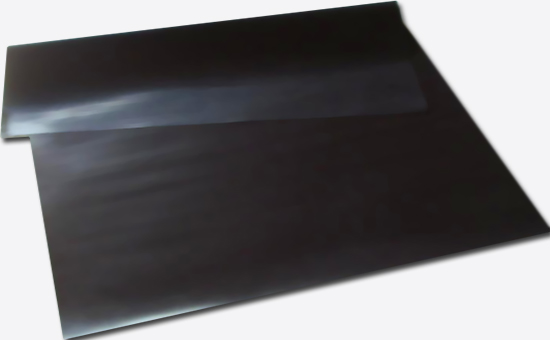

Butyl rubber has the characteristics of heat resistance, acid resistance, ozone resistance and weather resistance, and is an ideal raw material for the production of roof waterproofing membranes. Butyl reclaime…

-

Butyl rubber with low unsaturation has good thermal stability and can be used to produce heat-resistant rubber sheets. Butyl reclaimed rubber retains the basic performance characteristics of butyl rubber, with …

-

The price of reclaimed rubber varies from more than 1,000 yuan to more than 8,000 yuan according to different types and different indicators. It is not ruled out that the price of special reclaimed rubber can e…

-

As a typical non-polar rubber, butyl rubber has poor adhesion with metal materials, and is difficult to co-vulcanize and bond with other rubbers. It is necessary to take measures to improve the adhesive propert…

-

In actual production, butyl reclaimed rubber products can not only use sulfur vulcanization system, but also choose resin vulcanization system or quinone oxime vulcanization system; then how to match the basic …

-

When using butyl reclaimed rubber to produce rubber products, the design of the vulcanization system in the rubber formula directly affects the performance and performance of the finished product. The editor wi…