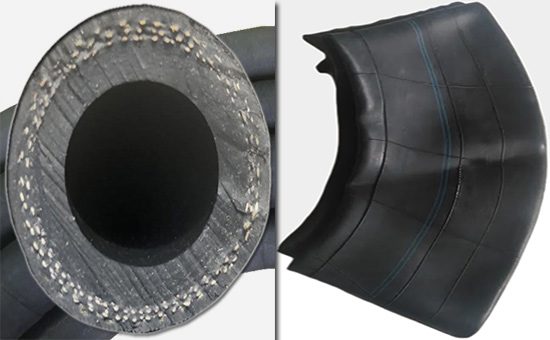

Extrusion is a process in which the rubber material is continuously pressed out of semi-finished products with a certain section shape and size through the mouth type through the extruder. During the production of rubber products such as inner tube, heat-resistant rubber tube and sealant strip with butyl reclaimed rubber and butyl rubber/butyl reclaimed rubber as main raw materials, the extruding performance directly affects the quality of finished products. What are the factors affecting the extruding performance of reclaimed butyl rubber? How to further improve the extruding performance of butyl reclaimed rubber?

The extruding performance indexes of rubber compound include extruding speed, appearance quality of semi-finished products, dimensional stability and stiffness of semi-finished products. In actual production, rubber compound formula, rubber filter, hot refining, rubber supply, temperature and moisture will affect the extruding performance of butyl reclaimed rubber.

1. How to design formula to improve the extruding performance of butyl reclaimed rubber

Plasticity directly affects the extruding performance of rubber compound. Compared with butyl rubber, butyl reclaimed rubber has better plasticity and better dimensional stability of semi-finished products. Therefore, blending butyl reclaimed rubber with pure butyl rubber is one of the methods to improve the extruding performance of rubber compound.

When butyl rubber/butyl reclaimed rubber are used together, it is difficult to press the rubber with a rubber content of more than 95% and less than 25%. When designing the formula of butyl reclaimed rubber products, it is recommended to control the rubber content to about 30%, which is more beneficial to the rubber pressing. In the filling system, the shrinkage of butyl rubber/reclaimed butyl rubber 2ELYY126 filled with quick press furnace black is small, and the extrusion performance of the rubber filled with clay is relatively better. In order to further improve the extruding performance of butyl reclaimed rubber, low-density polyethylene, paraffin wax, fatty acid ester, ointment, etc. can be used appropriately, and the dosage should be controlled reasonably to avoid the impact on the physical and mechanical properties of the rubber.

2. Improve the extruding performance of butyl reclaimed rubber by removing impurities through rubber filtering process

When butyl reclaimed rubber is used to reduce rubber products such as inner tubes, wires and cables, advance filtering can remove foreign impurities, lumps and undispersed. When the rubber material containing butyl reclaimed rubber needs to be filtered, it is recommended to add sulfur yellow before filtering and pressing; Properly adjust the formula and extend the scorching time. This is because after the rubber is filtered, impurities will be brought into the rubber material after adding sulfur, parking, hot refining, and mixing and returning to the rubber, resulting in surface defects of butyl reclaimed rubber extrudates.

3. Fully hot refining to improve the extruding performance of butyl reclaimed rubber

The butyl reclaimed rubber products must be fully hot refined when using the hot feed extruder for extrusion process to improve the extrusion performance of reclaimed rubber. During hot smelting, two or more open mixers shall be used, and the temperature of hyperthermia shall be controlled among 80-90 ℃ to facilitate the elimination of mixed gas.

4. Improving the extruding performance of butyl reclaimed rubber with roller forced rubber feeding

In actual production, when the rubber supply is equal to the extrusion amount, bubbles are easily mixed, and the dimensional stability of the semi-finished butyl reclaimed rubber is poor; It is recommended that the glue supply amount is slightly more than the press out amount, and the roller is used for forced glue supply to ensure that the glue supply is continuous and equal; If possible, use thin and wide adhesive tape to reduce foaming and mixing.

5. Properly increase the pressing temperature to improve the pressing performance of butyl reclaimed rubber

When the rubber products produced with butyl reclaimed rubber, butyl rubber/butyl reclaimed rubber and rubber as the main raw materials are pressed, the extrusion temperature is slightly higher than that of other synthetic rubbers, the die temperature is controlled among 100-120 ℃, the head temperature is 90-110 ℃, and the roller temperature is 80-100 ℃.

6. Avoid excessive moisture to improve the extruding performance of butyl reclaimed rubber

If there is much water in the compound of butyl reclaimed rubber and butyl rubber/butyl reclaimed rubber, bubbles will be generated when the extrusion temperature rises. Once bubbles are generated, it is difficult to discharge them. For example, when the size of the semi-finished product pressed out of the butyl inner tube does not conform to the standard, which results in a large amount of returned rubber, special attention must be paid to the mixing of bubbles; At this time, it is recommended to fully dry the returned rubber after spreading, add new rubber in the proportion of 10% - 20%, and use it after hot refining.

When using butyl reclaimed rubber or butyl rubber/butyl reclaimed rubber and using rubber for extruding process, appropriate measures must be taken to improve the extruding performance of rubber compound. Later, the editor will continue to discuss relevant issues with you.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits