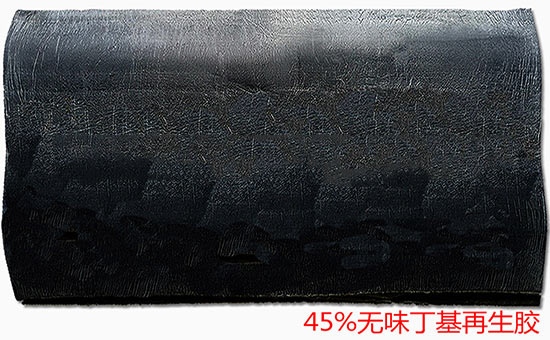

Heat-resistant rubber sheets need to be used under high temperature conditions for a long time, and have strict requirements on the heat-resistant aging performance of rubber. The heat resistance of rubber is closely related to the molecular structure of rubber. Butyl rubber with low unsaturation has good thermal stability and can be used to produce heat-resistant rubber sheets. Butyl reclaimed rubber retains the basic performance characteristics of butyl rubber, with good air tightness, heat resistance, and chemical corrosion resistance. Can it be used to produce heat-resistant rubber sheets? How to use butyl reclaimed rubber better in heat-resistant rubber sheet? Do I need to adjust the heat resistant rubber sheet formula?

1. Application of butyl reclaimed rubber in heat-resistant rubber sheet

Butyl reclaimed rubber has good heat resistance, good compatibility with butyl rubber and EPDM rubber, and can be used alone or with IIR, EPDM, EPDM reclaimed rubber, chlorinated butyl rubber, chlorinated Butyl reclaimed rubber 2ELYY713 is used in combination to produce heat-resistant rubber sheets, which can effectively reduce the cost of raw materials. In actual production, the combination of butyl reclaimed rubber and an appropriate amount of EPDM compound can further delay the aging time of heat-resistant rubber sheets; Rubber sheet, improve the vulcanization performance and heat resistance of rubber sheet.

2. Mixing skills of butyl reclaimed rubber in heat-resistant rubber sheet

Under high temperature conditions, the rubber will cause the cracking of the main chain and the destruction of the cross-linking network, or further cross-linking, and the mechanical properties will decrease. Therefore, when butyl reclaimed rubber is mixed with heat-resistant rubber sheets, the formula must be properly adjusted to further improve the heat resistance of the rubber.

(1) Vulcanization system: When using butyl reclaimed rubber as the main raw material to produce heat-resistant rubber sheets, it is recommended to use resin vulcanization such as phenolic resin to obtain better heat resistance; use butyl reclaimed rubber vulcanizate vulcanized with p-quinone dioxime Heat resistance is also better than sulfur vulcanizate.

(2) Reinforcing filling system: When adjusting the reinforcing filling system of butyl reclaimed rubber heat-resistant rubber sheet, it is necessary to comprehensively consider the mechanical strength, heat resistance and cost of the rubber sheet. In general, the better the reinforcing performance of the rubber reinforcing filler, the worse the heat aging effect of the vulcanizate; the inorganic filler has better heat resistance than carbon black. Therefore, butyl reclaimed rubber heat-resistant rubber sheet is recommended to be filled with silica, zinc oxide, magnesium oxide, and silicate fillers.

(3) Softening system: The softening agent has a great influence on the heat resistance of the rubber compound, and the low molecular weight softening agent is easy to migrate or volatilize at high temperature. It is recommended to use high molecular weight, high boiling point softeners, such as polyester softeners or reactive softeners, for heat-resistant rubber sheets mixed with butyl reclaimed rubber. In the production of heat-resistant butyl rubber sheet, it is recommended that the dosage of coumarone should not exceed 5 parts, or use 10-20 parts of vaseline or paraffin oil, mineral rubber and petroleum asphalt resin.

(4) Anti-aging system: choose high-efficiency heat-resistant anti-aging agent or use heat-resistant anti-aging agent and fatigue-resistant anti-aging agent together, butyl reclaimed rubber heat-resistant rubber sheet has good heat resistance; appropriately increase the amount of anti-aging agent, or mix two or A variety of antioxidants are used together to produce a better synergistic effect.

The reasonable use of butyl reclaimed rubber for heat-resistant rubber sheets can effectively reduce costs on the premise of ensuring product quality. The editor will continue to discuss related issues with you later.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits