Automobile shock-absorbing rubber products are elastic buffer devices installed in specific parts of the body made of rubber as the main raw material, which can play a role in reducing or eliminating vibration and noise during the driving of the car. Chlorinated butyl rubber is prepared by chlorine gas through butyl rubber solution, which has the characteristics of good air tightness, heat resistance, weather resistance, aging resistance, good shock absorption performance, etc., and is an ideal raw material for the production of various types of automobile shock absorbing rubber products.

1. The specific application of chlorobutyl reclaimed rubber in automobile shock absorbing products

Chlorobutyl reclaimed rubber is a waste chlorobutyl rubber products such as pharmaceutical butyl stoppers processed by crushing, thinning, desulfurization, refining and other processes, which retains the basic performance characteristics of chlorobutyl rubber, and can be used in combination with chlorobutyl rubber E4LYY1113 produce automobile shock-absorbing rubber products to reduce costs. Chlorobutyl rubber/chlorobutyl reclaimed rubber has good elasticity and can effectively absorb the vibration caused by uneven road surface during driving; Good damping and shock absorption, isolate sound wave conduction, and reduce internal noise.

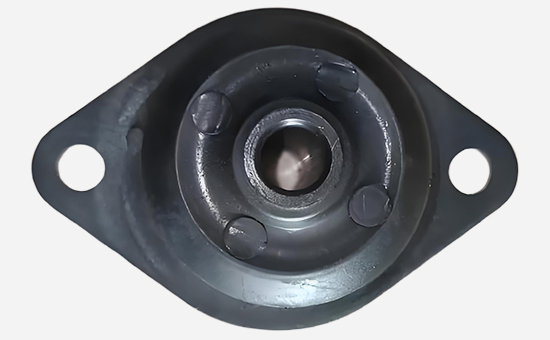

The shock-absorbing rubber products produced with chlorobutyl rubber/chlorobutyl reclaimed rubber combined with rubber as the main raw material are widely used in automobiles, mainly including shock-absorbing upper brackets in the suspension system, rear axle elastic couplings, inflatable shock absorbers, shock absorbing pads, spring pads, etc., the central bearing of the transmission shaft in the power transmission system, and various rubber bushings in the steering system. The vulcanization formula of shock-absorbing rubber products is different for different use occasions.

2. Chlorinated butyl rubber/chlorobutyl reclaimed rubber is used to produce vulcanization formula for automobile shock-absorbing rubber products

(1) Chlorobutyl rubber/chlorobutyl reclaimed rubber is used to produce automobile coordination balancer shock absorbing pads

80 parts of chlorobutyl rubber, 20 parts of chlorobutyl reclaimed rubber, 5 parts of zinc oxide, 1 part of stearic acid, 35 parts of carbon black N330, 30 parts of carbon black N990, 10.5 parts of naphthenic oil, 2 parts of accelerator TMTD, 0.5 parts of vulcanizing agent DTDM; A total of 184 copies.

(2) Chlorobutyl rubber/chlorobutyl reclaimed rubber is used to produce vulcanization formula for automobile bushings

70 parts of chlorinated butyl rubber, 30 parts of chlorinated butyl reclaimed rubber, 5 parts of zinc oxide, 1 part of stearic acid, 38 parts of carbon black N110, 5 parts of naphthenic oil, 1 part of accelerator DM, 1 part of accelerator TMTD, 1.5 parts of sulfur; A total of 152.5 servings.

(3) Chlorobutyl rubber/chlorobutyl reclaimed rubber is used to produce vulcanization formula for automobile body support pads

75 parts of chlorobutyl rubber, 25 parts of chlorinated butyl reclaimed rubber, 5 parts of zinc oxide, 40 parts of carbon black N330, 15 parts of carbon black N990, 20 parts of softener, 2 parts of accelerator DM, 1 part of accelerator TMTD, 1 part of sulfur; A total of 184 copies.

80 parts of chlorobutyl rubber, 20 parts of chlorinated butyl reclaimed rubber, 5 parts of zinc oxide, 0.5 parts of magnesium oxide, 1 part of antioxidant 2246, 15 parts of carbon black N880, 50 parts of easily mixed tank black, 15 parts of naphthenic oil, 1 part of accelerator DM, 1 part of accelerator TMTD, 2 parts of sulfur; Total 190.5 copies.

When using chlorobutyl reclaimed rubber to reduce the production cost of automobile shock-absorbing rubber products, it is necessary to select appropriate reclaimed rubber products according to the specific performance requirements of shock-absorbing rubber, reasonably determine the mixing ratio of reclaimed rubber, and appropriately adjust the production process formula and production process parameters; In the follow-up, Xiaobian will continue to discuss with you the key points of the production process of chlorobutyl reclaimed rubber mixed with various automobile shock-absorbing rubber products.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits