Customer Name: A Rubber Product Co., Ltd. in Hengshui Jing County

Product used: 5# tire recycled rubber

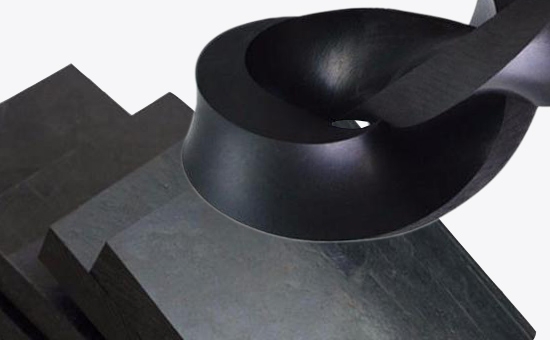

Use occasions: production of high-elastic rubber shock-absorbing blocks/shock-absorbing gaskets

How to use: completely use tire recycled rubber

Case Brief: A rubber product Co., Ltd. in Hengshui Jing County operates various industrial rubber sheets, insulating rubber strips, shock-absorbing rubber blocks/pads, etc. Since 2016, Hongyun 5# tire recycled rubber has been used to replace natural rubber and styrene-butadiene rubber. Elastic rubber shock-absorbing blocks and shock-absorbing rubber pads significantly reduce raw material costs and production costs, significantly improve product market competitiveness, and have achieved good economic benefits.

Coordination system: When the customer completely uses Hongyun 5# tire reclaimed rubber to produce rubber shock absorbers and shock absorber pads, the traditional sulfur vulcanization system is used to improve the crosslinking degree of reclaimed rubber, and the finished product has excellent shock absorption performance and dynamic fatigue resistance; Semi-reinforced carbon black and fine particle thermal cracking carbon black are used in combination, the shock absorber block/rubber pad has high elongation, good elasticity, aging resistance, low heat generation during use; light calcium filling further reduces costs; using spindle oil As a softener, it has a good softening and plasticizing effect; the anti-aging agent D improves the resistance of the shock absorber to heat, oxygen, flexion and other aging factors.

Encountered a problem: After the customer processed Hongyun 5# tire reclaimed rubber and the above compounding agent in a certain proportion, the physical and mechanical properties of the finished product meet the user's needs, but the product's heat resistance 2LLYY610 has poor performance, and frequent use under dynamic conditions will accelerate the reduction Aging time of the shock block.

Solution: After multiple experiments, the customer replaced the thermal cracking carbon black in the compounding agent with fast pressing furnace black to improve the heat resistance of the rubber compound and improve the processing performance of the rubber compound. Good thermal conductivity.

Use effect: After the customer adjusts the rubber product formula, the rubber shock-absorbing block and shock-absorbing pad produced by using Hongyun 5# tire reclaimed rubber have good elasticity and high toughness, and the rubber gasket can be folded in half without breaking. In the process, it can be cut at any position according to the actual needs. The shock absorption effect is good and the service life is long. It is suitable for shock absorption or sealing in various occasions. The market sales far exceed similar products nearby, and it has won unanimous praise from users in various industries.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits